Shops often exert a lot of effort toward selecting the best toolholder for a particular machining application. That’s because toolholders are important for effective and safe connections between high speed tools and a machine, and choosing the right toolholder is the key to greater precision, longer tool life and decreased machining costs.

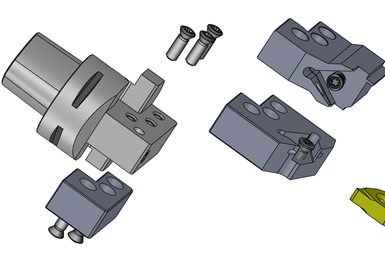

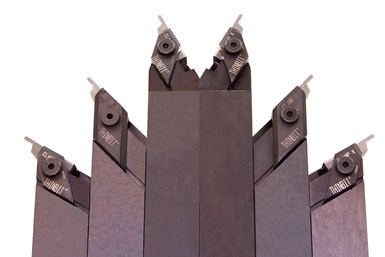

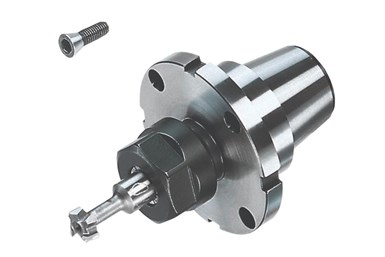

Every month, we’re putting together a Technology Showcase, highlighting some of the product information that PM received from supplier companies. For January, we focused on toolholders, including a modular tooling system with a coolant-through design; an online form tool service to simplify ordering holders and inserts; hydraulic chucks featuring tool-side clamping for faster and safer tool changes; and more.

Take a few minutes to check out some of the latest new and/or improved products in the precision machining industry as described below. For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s December Technology Review.

Click on each link below to read the full product post:

Related Content

Piezoelectric Sensor Technology: Moving Toward more Efficient Machine Monitoring

A new system that uses simple and compact force or strain sensors, which can be integrated inside toolholders or mounted on surfaces such as spindle housings, can facilitate CNC machine monitoring.

Read MoreMachining’s Impact on Sustainability

Individual elements of the machining process such as machine tools, tooling and even CAD/CAM software play a role in overall machine shop sustainability. Observing the entire process especially when it comes to their influences on energy usage is key.

Read MorePMTS 2023 Product Preview: Toolholders

Learn about some of the latest toolholder solutions that will be on display at PMTS 2023.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MoreRead Next

Precision Machining Technology Review December 2021: Parts Cleaning

Production Machining’s Parts Cleaning Showcase includes CTG, Kyzen, Ecoclean, Renegade, Cortec and Solvent Kleene.

Read MorePrecision Machining Technology Review October 2021: Measurement

Production Machining’s measurement showcase includes OGP, Hexagon, LK Metrology and more.

Read MorePrecision Machining Technology Review November 2021: Workholding

Production Machining’s workholding showcase includes SMW Autoblok, Forkhardt, Mate Precision Technologies, Norgren, Jergens and Platinum Tooling.

Read More