Every month, Production Machining puts together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For November, we focused on workholding.

Precision manufacturing would not be precise without workholding to hold the parts in a fixed position because how a part is held is often as important as how it is cut. Holding the workpiece precisely is an integral aspect of the machining process – delivering accuracy and production capabilities as well as saving setup time with faster changeovers.

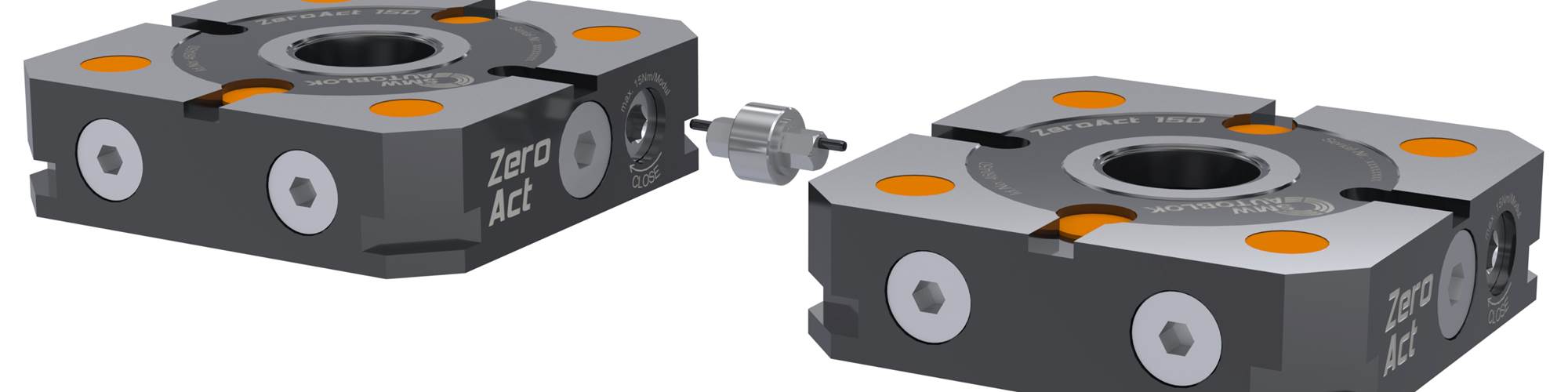

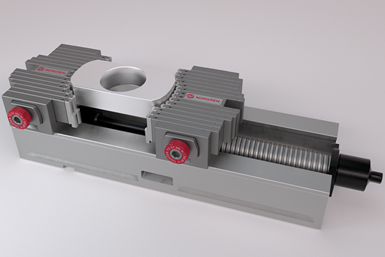

In this technology review, we’re looking at a connectable workpiece positioning system for manual and electric zero-point clamping; a universally applicable, wedge-style power chuck; a zero-point workholding system engineered to maximize holding power for three-, four- and five-axis machining centers; and more.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s October’s Technology Review.

Click on each link below to read the full product post:

Related Content

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreBreaking the Barriers for Small Tool Breakage Detection

This contact-free tool breakage detector, especially useful for machine tools with small tools and small workzones, offers a quick and efficient way to change out broken tools before they cause bigger problems.

Read MoreThe Value of Swiss-Types Milling Rectangular Medical Parts

High-speed spindle technology was key to effective milling of small cardiac monitoring components complete on a CNC sliding-headstock machine platform instead of running them across two mills.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreRead Next

Precision Machining Technology Review October 2021: Measurement

Production Machining’s measurement showcase includes OGP, Hexagon, LK Metrology and more.

Read MorePrecision Machining Eastec Technology Preview September 2021

Production Machining highlights some of the latest precision machining advances and technology updates that will be showcased at Eastec 2021, Oct. 19-21 in West Springfield, Massachusetts.

Read MorePrecision Machining Technology Review August 2021: Cutting Tools

Production Machining’s cutting tools showcase includes Horn USA, GWS Tool Group, Greenleaf Corp., Platinum Tooling and more.

Read More

.jpg;maxWidth=300;quality=90)