The precision machining industry would be lost without measurement. Measurement systems are an integral part of measuring and determining the quality and precision of parts; confirming or improving a process; and identifying and measuring any issues or errors so systems can be corrected and optimized. Faster, more accurate measurement results can lead to increased productivity in the manufacture of high-volume precision machined parts.

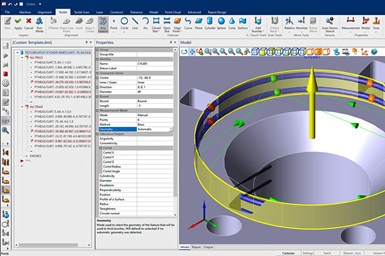

Every month, Production Machining puts together a Technology Showcase, highlighting some of the product information that PM receives from supplier companies. For October, we focused on the important area of measurement, including a lens turret system that enables automatic lens changes as part of a CNC program; a multi-sensor radio probe system designed to improve ease of in-machine measurement configuration and handling in a range of manufacturing environments; a CMM measurement, programming, analysis and reporting software that has been updated to increase inspection productivity, improve the quality of data collected and gain better insight into the components being measured; and more.

For the latest new products across the broad spectrum of precision machining, check out Production Machining’s New Products online.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Read PM’s September’s Technology Review.

Click on each link below to read the full product post:

Related Content

Automated Inspection Transforms Medical Manufacturer’s Quality Control

Manual steps for part inspection have been eliminated with a new CMM process using more advanced software and strategies such as using a combined scanning/touch-trigger probe.

Read MoreThe Advantages of Automated Shopfloor Gaging

This “parallel kinematic” gage offers the opportunity to automate and improve machining process control for shops endeavoring to move from sample inspection to 100% inspection.

Read MoreReplace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MoreRead Next

Precision Machining Eastec Technology Preview September 2021

Production Machining highlights some of the latest precision machining advances and technology updates that will be showcased at Eastec 2021, Oct. 19-21 in West Springfield, Massachusetts.

Read MorePrecision Machining Technology Review August 2021: Cutting Tools

Production Machining’s cutting tools showcase includes Horn USA, GWS Tool Group, Greenleaf Corp., Platinum Tooling and more.

Read MorePrecision Machining Technology Review June 2021: Machining Centers

Production Machining’s machining centers showcase includes Absolute Machine Tools, Porta Solutions, Expand Machinery, Romi Machine Tools and more.

Read More