Reducing Downtime With Tool Presetting

It’s an ongoing challenge. To remain competitive, shops must find new and more efficient ways to increase production. Often they look to new, faster and more precise machine tools as the answer. Sometimes experimentation with a variety of different tooling

It’s an ongoing challenge. To remain competitive, shops must find new and more efficient ways to increase production. Often they look to new, faster and more precise machine tools as the answer. Sometimes experimentation with a variety of different tooling solutions brings added savings in cycle times. But seldom is enough time spent refining the setup process to minimize interruptions and keep the machines cutting.

To get the most out of the machines on the floor, a shop must keep them producing parts. When part runs are short, reducing machine downtime becomes even more vital, and tooling setups must be highly efficient. Naturally, having the tools preset and ready for the next operation allows for faster change-over from one job to the next, keeping a machine’s idle time to a minimum.

Offline tool presetting is sometimes viewed as an excessive and unnecessary cost, but without it, the operator depends on a far more expensive, yet often less accurate, presetter—the machine tool itself—to handle the tooling setup. As long as the machine is being used to touch off tools to establish initial tool offsets and to cut trial parts, it cannot be making money for the shop. This significant draw on spindle cutting time can make the difference in a shop’s

profitability.

Take It Offline

A common approach to supplying the machine tool with the necessary tooling is to allow (or require, depending on the point of view) each machinist to gather the tools from a central location and bring them to the machine for setup. In this scenario, the tool crib attendant is responsible largely only for managing tooling inventory. The machinist, on the other hand, spends a significant amount of time gathering the necessary fixtures and tools and loading each of them into the machine to get the job running. Compounded with the process of manually touching off the tools once they are loaded into the machine, running trial parts and sending them through inspection, a large percent of the machinist’s job has been consumed with functions outside of machining. And part production pays the price.

To alleviate the lost production time, a solution that more shops are implementing is to place a skilled machinist in charge of the tool crib. Using his or her knowledge of the operations that the shop runs, as well as the tooling requirements, he or she brings together the necessary tooling and fixturing for each job, presets the tools and establishes the offsets before the tooling is needed. This preliminary work allows the machinists to focus on production; when a machine requires a change-over, the tooling is ready to go. Setups are therefore greatly reduced, often saving 15 minutes or more for each setup.

The key to offline presetting is quality tool presetting equipment with a high level of precision and repeatability to allow the setup personnel to provide the machinist with what he needs, done right so the first part off is to spec. Then the reduction of setup time should be enough to compensate for any added equipment or personnel.

Set The Tone

One company that has found the benefits of tool presetting is Straumann Mfg. Inc. (Andover, Massachusetts), a provider of precision dental implant systems. This subsidiary of Swiss-based Straumann Holding, one of the world’s largest dental implant companies, opened its current location, a 160,000-square-foot facility that includes a training center, simulation and dental lab facilities and an auditorium, in 2005.

The manufacturing floor at Straumann, notably clean and well managed, currently houses Citizen and Traub Swiss turning machines. According to Bob Boyle, group leader and programmer for the manufacturing group, a lot of the philosophy from the Swiss headquarters carried over to the U.S. facility.

“People work hard here to keep the plant floor clean and processes streamlined, and it shows in the smooth production operations,” Mr. Boyle explains. “We do approximately 2 million parts per year at this facility—all dental implants and associated components.”

A machine that is seeing increased presence on the Straumann floor is the Traub CNC machine. It is with this machine that Mr. Boyle begins his explanation of the significance of tool presetting in the company’s operations. “In the beginning, with only one Traub running, it was easy enough to keep the tooling ready for this machine with a manual presetter,” he says.

For this machine, the company uses a Traub manual presetter, with which the machine operator sets the tooling to the exact tolerances as required by the machine tool. This process can be done offline while the machine is running with other tooling, therefore having a backup ready as soon as it is needed. The operator simply sets the tool length within a certain range—too long and the tool will wobble as it cuts, too short and the toolholder will cause interference in the machine.

Higher Precision

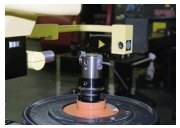

Presetting the tools for the lineup of Citizen machines on the floor is another story. For these machines, the company has invested in a Zoller Hyperion 250 horizontal tool presetter for its higher accuracy, repeatability and ease of use. Mr. Boyle clarifies, “It’s not that we’re less concerned with the accuracy on the Traub. We just want to be sure of how many of each type of machine we will be bringing in before investing in the adapters necessary to set up the Traubs. We may even bring in a second Zoller for those machines.”

Skip Benanti, the tool management technician, spends his work day on the Zoller, presetting all of the tooling for each of the Citizen machines. He’s an experienced machinist with a solid understanding of the operations being performed. He knows how long the tooling will typically last for each particular job so he can determine which tools to preset at any given time.

“In contrast to the 10- to 20-micron accuracy of the Traub manual presetter, the Zoller can measure down to a single micron,” Mr. Benanti explains. “It’s extremely accurate, and it eliminates the touch and feel issues you get with a manual presetter. It takes a snapshot of the tool precisely as it sees it. The human aspect is taken out of the equation as far as accuracy goes.” Tools can be quickly set up and inspected for tool runout and concentricity, tool geometry and tool wear and then preset to nominal length and diameter position.

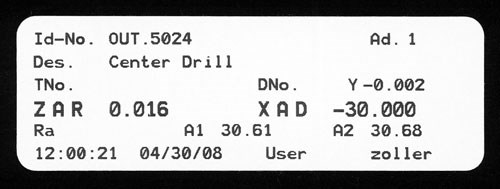

Mr. Boyle sees a significant time savings with changing a tool in the machine, too. “Once the tools are preset, we print a tag with the values that goes with the tooling to the machine,” he says. “The numbers are entered into the tool data for the machine, including variable and offset values, so the machine can recalculate its zero point from there. It knows right where the tool tip is. All the data’s right there.”

Manufacturers depend on tool accuracy to produce the highest quality products for the customer. Without the dimensions of the tool, the machine that uses that tool becomes unreliable. The Zoller system has been in operation at Straumann since the U.S. operation opened, and it has been a catalyst in helping the company reduce machine downtime, decrease tool inventory, lower scrap rate and increase part quality. Mr. Benanti summarizes, “For today’s machining, the time savings you get out of it and the accuracy—which saves time in setups and running—make it invaluable for us. It pays for itself in the first year, without a doubt, with the production.”

Related Content

Shop Finds Value in Simple CMM Programming

Icon-driven programming enables all shopfloor personnel to perform CMM inspection, not just those in the quality department.

Read MorePMTS 2023 Product Preview: Measurement

Learn about some of the latest measurement solutions that will be on display at PMTS 2023.

Read MoreDoes a Scanning Probe Make Sense on a Swiss-Type?

Swiss-types have limited tooling capacity, but there can be advantages to giving up some of that capacity to take advantage of a touch probe — in fact, a scanning probe — to enable in-process part measurements.

Read MoreReplace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.

Read MoreRead Next

Setting Tools Makes Small Shop Sense

Some people think tool presetting can be justified only in large operations. This Arizona shop shows how it makes sense almost anywhere.

Read MoreCutting Time

This company modified its production process to cut not just metal, but also setup time, costs and the effects of the labor crunch.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More

.jpg;maxWidth=300;quality=90)