Shop Improves Turning with Indexable Coated Carbide Inserts

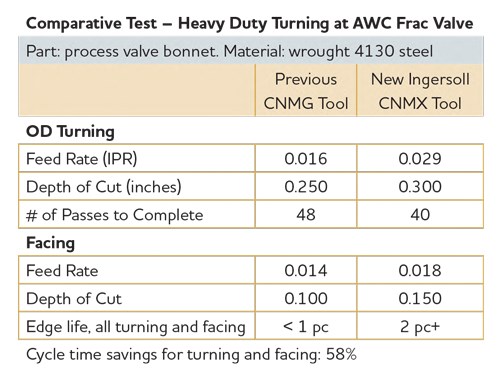

This shop retooled a heavy duty OD turning and facing job for gummy 4130 steel. It tripled the material removal rate and more than doubled tool life after making this change.

Heavy turning of gummy metals usually forces an operator into a “triage dilemma;” they must choose among good cycle time, improved chip control or long tool life, but achieving all three at once, or even two of the three, is not possible. Cutting deeper improves chip control and speeds up the operation, but it raises the risk of rupturing the tool at any moment. Cutting shallower may prevent tool rupture, but it slows down the operation, requires more passes and can create long, stringy chips (with all their associated baggage).

However, there is no triage dilemma at AWC Frac Valve, Conroe, Texas, which manufactures very large valves for the oil and gas industry and generates chips the size of cornflakes in the process. The company, a division of Archer Well, is a 35-man shop that runs 24/5.

AWC avoided the dilemma by retooling a heavy duty OD turning and facing job for gummy 4130 steel. The company tripled the material removal rate and more than doubled tool life after making this change. Moreover, it completely eliminated sudden edge failures that had interrupted production previously and forced a lot of re-working.

“Previously, we had to keep two back-up tools in the turret just to keep things going when one tool popped,” says Jim Beaver, assistant production manager. “Often, the tool would rupture midway through the first piece.”

The new tool AWC implemented is an Ingersoll CNMX Gold-Duty indexable coated carbide insert. With aggressive top face geometry in an advanced seat pocket scheme, it is a generation ahead of the field in large-scale turning, according to Ed Woksa, Ingersoll national turning product manager. AWS is one of the first users of the new insert, he added.

Now the big chips peel off in easily controlled “sixes and nines,” reducing a 480-pound billet of 4130 steel to a 250-pound valve bonnet in about 45 minutes on a Doosan 400LM turning center. The job used to take about 2 hours and usually shattered one tool per part.

Long Tool Life Requirement

The retooling began when Jim Beaver set a new tool life requirement for the operation: two pieces per edge, minimum. Their standard insert at the time, an older conventional CNMG negative-rake tool, rarely lasted through one part. The new requirement was part of a plant-wide “continuous improvement” initiative that Mr. Beaver was charged to implement.

Mr. Beaver pointed out the challenge to Ingersoll’s Mike Salewsky during their regular weekly plant walk-through. Because of the operation’s scale and the cutting forces involved, Mr. Salewsky brought in Ingersoll field turning product manager Eric Strieby. The new CNMX tool he recommended was being put into production at the time, so Mr. Streiby offered a free, no-risk, on-site test.

“It was like a beta test, but on a commercialized tool,” says production manager Kirk Cudd. “Should the tool break during the test, we wouldn’t have to pick up the tab.” By contrast, many tool providers offer on-site testing and price reduction to try a tool, but only after the customer purchases the tool and pays for any replacements.

CNC lead man Ben Molinar ran the test on live parts on site, with Ingersoll guidance. He ran heavy OD roughing, OD finishing and facing on 4130. Mr. Beaver also tested the latest CNMG inserts from two other providers, but neither met the tool life requirement consistently.

Fine Tuning Pays Off

Once the tool proved out operationally with the parameters established in the test, Mr. Beaver did some fine tuning. He eliminated the two back-up tools from the turret and ramped up the depth of cut to 0.325 inch for turning and 0.225 inch for facing. Still, the inserts lasted through at least two parts with no ruptures.

“Now the failure mechanism is gradual wear, not fracture, and the indicator for edge change is simply loss of finish,” Mr. Beaver says.

Not surprisingly, tool related production stoppages disappeared altogether and tool servicing labor costs dropped significantly at AWC. Mr. Beaver puts the annual all-in saving associated with the retooling at $75,000 for this job alone.

Improved Insert Geometry

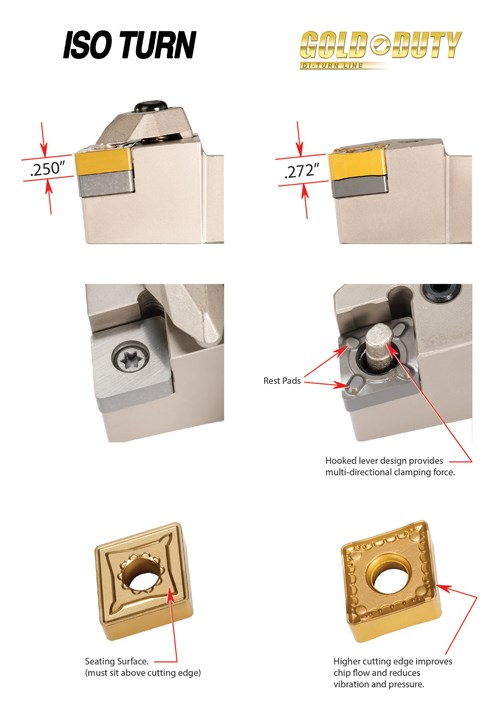

The Ingersoll CNMX tool succeeded here by combining improved top face geometry versus conventional CNMMs and CNMGs with an advanced seating system that makes the new geometry possible.

“You can see the wide front edge that really breaks up the chips on a gummy metal,” Mr. Beaver says.

CNMMs are neutral rake with a negative land at the cutting edge for added strength, better chip breaking and improved chip flow. This allows higher feed rates to be applied. But they must be single-sided because a positive-rake tool cannot be flipped without damaging the cutting edges with the clamping forces. By contrast, CNMGs that are designed for heavier cuts are two-sided, but normally have neutral or slightly positive rakes (0 to 6 degrees), which raise cutting forces.

“The new seating arrangement in the CMMX makes it possible to get two sides plus aggressive, positive geometry in the same insert—something never available before,” says Ingersoll’s Ed Woksa. “Thus, you can cut deeper without overloading the insert and still get the second side.”

Unlike flat insert seats found with conventional toolholders, the Ingersoll CNMX seating scheme is based on four “rest pads” on the insert that mate with dimples in the seat. Thus, it’s the rest pads, and not the cutting edges, that bear the clamping forces. As a result, the cutting edge can be 5 degrees positive, for freer cutting, without risk of clamping damage.

“Tooling performance aside, Ingersoll was easy to work with on a very risky operation,” Mr. Beaver says. “Besides, we were looking for a tool life improvement only and wound up with a cycle time savings as well.”

Looking ahead, he sees at least 10 other heavy turning jobs where the new Ingersoll CNMX would likely bring about the same improvements.

For more information from AWC Frac Valves, call (936) 760-3431.

Related Content

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read More4 Strategies for Managing Chip Control

Having strategies in place for managing chips is an important part of protecting the production process, from tool life to product quality.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreRead Next

Repeatability with Heavy-Duty Vertical Turning

Developments in vertical turning technology, such as multitasking functionality, have further increased these machines' relevance.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreSeeing Automated Workpiece Measurement in Real Time

User-friendly inspection software for CNC machining centers was shown at IMTS 2024 monitoring measurements between and after machining while performing SPC based on recorded measurement values.

Read More

.png;maxWidth=300;quality=90)