Taking a Turn Toward Production Flexibility

Swiss-type screw machines provide unparalleled machining capabilities when it comes to processing small, detailed parts.

Swiss-type screw machines provide unparalleled machining capabilities when it comes to processing small, detailed parts. However, many of today’s shops are now diversifying and taking on more jobs involving medium-to-large-sized workpieces and those requiring five-axis machining that tend to exceed the part size realm of Swiss-type machines. Additionally, frequent production changes because of constantly fluctuating industry environments dictate a critical need for flexibility to quickly adjust part volumes, switch from one job to the next and squeeze in frequently occurring hot emergency jobs.

If a manufacturer is producing a specific part at high volumes, but the market for that part suddenly changes and only requires half of that volume, the manufacturer must quickly adjust production accordingly. With a shop floor equipped for strictly high-volume work, manufacturers can be limited in the kinds of new jobs they can take on to fill such production gaps. And if there is existing work to fill the gap, switching the shop’s current machines over for it may take days, costing even more valuable production time.

To better survive these production ups and downs, many of today’s medium-to-high-volume shops are diversifying their high-volume operations with twin-spindle, twin-turret, Y-axis capable turning centers such as Mazak’s Hyper Quadrex 200 MSY. Equipped with an optional bar feeder, the machine offers all the performance of a high-volume machine, but with the added benefit of accommodating a range of part sizes on the same machine. It also allows a shop to change over jobs in a matter of minutes as opposed to days.

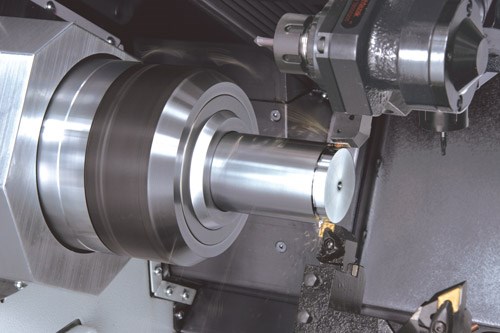

The turning center performs both chuck and bar work simultaneously for further increased production flexibility. Shops can take on jobs that involve chucked workpiece sizes as large as 13.5 inches in diameter and bar-fed parts from 0.25 to 2.5 inches in diameter, processing both cylindrical-shaped components as well as prismatic parts. With Y-axis capabilities, the turning center allows shops to do off-centerline machining and complete parts in single setups through multitasking operations.

Basically, this model combines the capabilities of two separate types of turning machines into one space-saving system. The machine’s footprint measures 137.6 inches × 103 inches.

Both of the machine’s spindles offer equal power and speed at 5,000 rpm and 30 hp each, as well as full C-axis CNC control for part positioning and contouring at a resolution of 0.0001 degree. These spindles can operate together or separately, allowing a single part to be machined on all surfaces through a coordinated “hand-off” between the two spindles, or two different parts can be machined simultaneously on one machine.

The upper and lower 12-station, 24-position tool turrets accommodate fixed and rotating tools. Both turrets mill with 7.5-hp rotary tool capability. These turrets can operate independently or together on the same part, creating opportunities for the machining of two features simultaneously or balanced machining strategies.

VDI toolholding on the turrets make for fast and reliable setups. Instead of requiring the removal of as many as four bolts to change a tool, these holders can be removed with one turn of an Allen wrench.

In balanced cutting operations, upper- and lower-turret X axes arranged inline work together on the same feature as rough and finish turning, rough and finish milling, or opposed feature drilling, tapping or boring. In cases where the part configuration permits, balanced machining increases metal removal rates.

The Y-axis stroke capabilities of 4 inches on upper turrets and 2.75 inches on lower turrets provide efficient machining for a variety of workpieces, and the lower Y axis allows for the use of small steady rests or tail center attachments.

Also featured on the machine, Mazak’s MX hybrid roller guide system is engineered for durability and reliability to provide long-term accuracy. It is designed to increase vibration dampening to extend tool life, handle high load capacities, offer quick acceleration and deceleration to shorten cycle times, consume less oil for “greener” operations, and last longer with less required maintenance.

Related Content

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreGetting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.

Read MoreCAM-Driven Lathe Questions

There can be hidden issues using legacy cam-driven lathes that can be overcome using new CNC technology. Here are three to keep in mind.

Read MoreRead Next

Boost Throughput With Multitasking

As a shop’s typical workload moves beyond high-production turned parts, new ways to reduce leadtimes and improve machining accuracy are evolving.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.jpg;maxWidth=300;quality=90)