13 Tips for the Perfect Trade Show Booth

Here are some tips to step up your game at your next trade show.

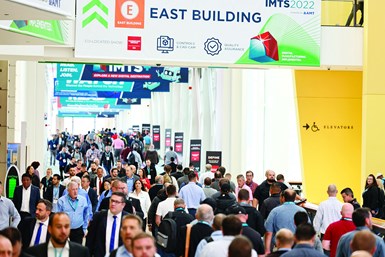

This year’s edition of the biennial International Manufacturing Technology Show was one for the ages. The show provided opportunities to see hundreds of new technologies in production machining, including smart sensors, smart devices, robotic machine tending, predictive analytics, artificial intelligence and machining learning. It also offered an opportunity to view the best in trade show booth design and practices. Want to step up your game at your next trade show?

Years ago, I used a broker to sell a boat I owned. He explained to me the importance of first impressions; that when a potential buyer approaches a yacht and immediately likes what they see (shiny topsides, sparkling deck, oiled teak and more), they will spend the rest of their review finding attributes that validate their first impression. In other words, if they like what they see, they are more likely to buy. The reverse, he explained, was also true. If their first impression is that things are unkept, disorderly, dirty and not well cared for they will immediately begin looking for more examples of things that aren’t quite right. As his theory went, these people would never buy.

The exact same is true of your trade show booth. If an attendee walks by your booth and it’s messy, disorderly and not engaging their interest in whatever you have to offer, they will stop dead. Conversely, if the booth is neat, clean, professional, interactive and engaging they will dig deeper and be more likely to express genuine interest. If you want to walk away from your next trade show with a huge pile of leads consider these tactics:

- Plan ahead! Meet weeks if not months in advance of the show to plan the booth space, who will attend, what marketing materials to bring and what will be on exhibit. Make sure everything required is in working order and prepare a checklist of what must be completed before the event.

- Make your booth experiences interactive. It’s one thing to tell your attendees about your new technology but it’s better to show them, and better yet to enable them to experience it for themselves. For every interactive item in the booth there should be someone there to competently demonstrate and explain it.

- Arrive each day in plenty of time to make sure the booth is set up, lights are turned on and all equipment is fully functional before the show hours begin. If equipment requires batteries, they best be fully charged and bring enough of them to make sure equipment is powered throughout the day.

- Electrical cords and other cables should be virtually invisible — tucked under tables and behind booth displays as necessary and properly secured underneath or to the floor with gaffing tape for the sake of appearance and safety.

- If your space includes tablecloths and runners, make sure they are wrinkle-free and square. A small, handheld steamer works wonders.

- Add a video screen to the booth. Use it to feature product demonstrations as well as customer quotes and testimonials.

- Most booth displays include lighting. While it may be easier to skip using it, a well-lit backdrop makes a subtle but instantly noticeable difference in the appearance of the booth.

- Stow personal belongings, bags, cups and the like out of sight.

- Begin setup early enough so the booth is ready and team members have plenty of time to prepare themselves for the day before show hours begin. This includes professional dress as appropriate for your audience. Suits and ties have become the exception which makes those who wear them look even more like they mean business.

- Stand up for yourself – and your booth visitors. Remove all chairs from the booth and skip the table across the front that puts a barrier between and separates you from your visitors.

- Condition those working the booth that their job is to engage attendees. Compare two booths, the first one has two people slumping against the backs of their chairs behind a table full of parts. The second includes two people standing at the front of the booth greeting attendees in a friendly fashion and welcoming them into the booth to learn more. Which of the two goes home with more opportunities … every time ?

- Never tear down early. Doing so is unprofessional, insulting to attendees who are still present and creates the risk that you’ll miss out on a great new opportunity from later visitors.

- Take your time packing up. At the end of a long show there’s a temptation to rush through the process and get on the road toward home. The old adage “the lazy man works twice as hard” will ring true here when, come the next show, components and tools are misplaced or missing altogether and setup will consist of one frustrating delay after another. Take a deep breath and return items to their rightful spots and conditions.

Successful trade show booths are all about the details. Attend to yours, set your company apart, secure new clients and grow your business.

Related Content

Tips for Troubleshooting and Repairing Chip Conveyors

A nonfunctioning chip conveyor can cause a high-production machine to be down for an extended period of time. Here is some troubleshooting advice if you’re having issues with your chip conveyors.

Read MoreVideo: Why a Production Machine Shop Started a Baseball Bat Company

A 153-year-old manufacturer of precision, metal pins recently started a side business creating custom wooden baseball bats. The reasoning behind establishing this new company is intriguing, as is how it has helped create a stronger bond with the local community.

Read More3 Common Filtration Questions Answered

Learn about the variety of filters for removing particulates from a cleaning fluid, how to determine cleaning fluid life and more.

Read MoreWhen a CNC Turn-Mill Doesn’t Turn

A shop in Big Sky Country uses a B-axis multitasking machine to produce complex, prismatic medical parts that require no turning complete from barstock.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.png;maxWidth=300;quality=90)