Video Tech Brief: Vacuum-Assist Collection of Small, Machined Parts

Marubeni Citizen-Cincom offers an optional vacuum collection system for very small parts machined on its Swiss-type CNC lathes to avoid losing or damaging parts. Main system components are 3D-printed made at its U.S. headquarters.

Automated removal and handling of parts after machining can be challenging, especially for very small parts that might get lost in the chip conveyor or traditional parts chute, and/or can’t impact each other causing their surfaces to be marred.

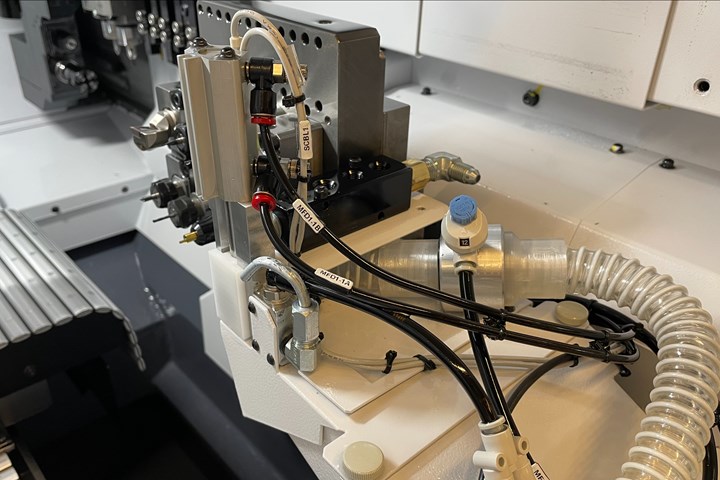

For Swiss-type lathes such as its L20 XII B-axis machine with automatic tool changer, Marubeni Citizen-Cincom offers an optional vacuum ejection system to pull and collect small parts once machining is completed.

As described in the video above, the system consists of a 3D-printed device that creates the vacuum and pulls completed parts ejected by the spindle through a tube and into a 3D-printed collection device. The collection unit’s funnel shape slows parts so as not to damage them as they gently fall to the bottom of the unit. The system uses either a timer or sensor to determine when a part has entered the collection unit to then shut off the vacuum device.

Related Content

-

6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

-

Choosing the Right Machine for Turned and Milled Medical Parts

The medical market is known for exceptionally tight tolerances and difficult materials, which means that selecting the proper machine is necessary to ensure a job is profitable.

-

Getting More Production From Swiss Turning Centers

Buying a new CNC Swiss turning center is a substantial investment. For the best return, look closely for capabilities that enable the best utilization of the machine.