Playback speed in this video was increased while the gripper accessed another pallet from the machine’s storage rack.

Challenge Machine takes advantage of a laser probe installed on the side of its new five-axis machine’s swiveling B-axis casting for tool presetting and, during an unattended machining cycle, to check for tool breakage and track tool wear (for some applications).

Blaine, Minnesota’s Challenge Machine specializes in machining small, complex parts — some exceedingly small. It does this using a range of equipment, including B-axis Swiss-type lathes, VMCs with trunnion tables that provide fourth- and, in some cases, fifth-axis rotation, and high-speed, true five-axis machining centers.

Although the shop has been able to realize long stretches of unattended machining with its bar-fed Swiss-types, until recently all of its milling equipment required manual part loading. However, its most recent five-axis machine features an integrated workholding pallet changer and high-capacity automatic toolchanger (ATC) to enable it to run unattended during the day and lights-out during the evening. In addition, CNC functionality combined with touch-probing routines simplifies programming because operations are created based on one kinematic point that creates one work coordinate system.

Machinist Brandon Gill is Micro Pro’s primary programmer, setup person and operator. He appreciates functions such as the capability to program operations based on one kinematic point/work coordinate system using Micro Pro’s Heidenhain TNC 640 CNC and probing routine, rather than programming with G54 or G55 G-code offsets.

The automated five-axis machine is a Micro Pro from Germany’s Kern Microtechnik (known in the United States as Kern Precision, located in Addison, Illinois). Aaron Schreiber, Challenge Machine’s general manager, says the shop had been considering this sophisticated machine platform for 15 years, one he admits represents no small investment. However, the shop decided to pull the trigger in late 2019 because it was experiencing accuracy, repeatability and surface finish issues for a growing number of medical parts the ISO 13485-certified shop was running on some of its five-axis trunnion machines. Plus, he notes that features such as cooling channels throughout the new machine that mitigate thermal growth also facilitated reliable machining for complex parts that typically have long cycle times. This, in addition to other machine capabilities, gives the shop the confidence to set it up to run on its own for days or even weeks.

Let It Run

Jim Betland started Challenge Machine in his basement in 1999. Early on, a large portion of the business was devoted to micromachining parts for the semiconductor industry. The shop, recently purchased by Assurance Manufacturing in Minneapolis, still focuses on the small stuff. (I’m talking in terms of part size and minding important micromachining details.) Schreiber says sales are up 15% this year as the shop increases its focus on the medical market while also targeting aerospace work.

The shop has machined a range of parts from various materials on the Micro Pro. In a typical month, it runs 10 to 15 different part numbers across the machine, many having cycle times upward of 3 hours.

According to Kern, the Micro Pro — which features hydrostatic guides, linear drives and a single-casting base made from ultra-high-performance concrete (UHPC) — achieves better than 2 microns positioning accuracy and better than 1 micron repeatability. It was designed with small-parts machining in mind, offering XYZ travels of 350 by 220 by 250 mm, while its swiveling B axis rotates 220 degrees. Schreiber notes that its small footprint of 43 square feet is appreciated given that floor space is currently at a premium in the shop’s 16,000-square-foot, environmentally controlled facility. (He says this is one reason the shop is likely to move to a different location in the coming years.)

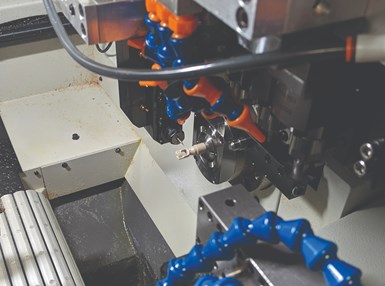

Cutting tools and workholding pallets are stored on the side of the machine. This machine can accommodate 30 workholding pallets and 109 tools. The smallest tool the shop has used on the Micro Pro (which has a 43,000-rpm HSK 40 spindle) is 0.003 inch in diameter.

Challenge Machine’s Micro Pro uses an Erowa zero point workholding system with power chuck that provides repeating positioning accuracy of less than 0.0001 inch. The machine can store 30 pallets and 109 toolholders in its enclosed, multilevel racks along one of its sides. The integral workpiece changer automatically delivers pallets with raw material (commonly round stock held in collets in Challenge Machine’s case) to the chuck, and removes and stores pallets once parts are completed.

The workpiece and tool storage capacity offers the shop versatility in the types of jobs it runs across the machine. For example, redundant tooling can be loaded into the machine when batch sizes of the same or similar parts are high. (Schreiber says batch sizes for this machine typically tops out at 100 to 300 pieces.) Conversely, various different tools (and pallets with raw material) can also be loaded so it can concurrently run a mix of low-volume jobs.

The integral workpiece changer automatically delivers pallets with material (commonly round stock held in collets) to the worktable and removes pallets once parts are completed. An Erowa zero-point workholding system features power chucks that provide repeating positioning accuracy of less than 0.003 mm.

Although batch sizes for this machine are seemingly low (much of the shop’s work is prototypes and low production volumes), part cycle times are often high. It sometimes runs unattended for 3 weeks straight, and 3-hour cycle times for a part are not uncommon. For example, the Micro Pro completes a titanium medical component used for aortic valve repair having walls measuring 0.014-inch-wide from 1.25-inch-diameter barstock in which 97% of the material is removed.

Here, a chuck is used simply for manual unloading of completed parts and loading of new material.

For applications such as this and impellers for blood pumps, full-five-axis contouring is required. However, the shop also benefits by performing 3 + 2 positioning operations for more prismatic parts, rather than running them across multiple machines or performing multiple setups.

To offer further confidence to run the Micro Pro unattended, Challenge Machine takes advantage of the Blum-Novotest laser probe which is mounted on the side of the machine’s swiveling B-axis casting for tool presetting and, during unattended machining cycles, to check for tool breakage and track tool wear (for some applications).

Machinist Brandon Gill is the Micro Pro’s primary programmer, setup person and operator. He says one small challenge with this machine was becoming familiar with the Heidenhain TNC 640 CNC (the shop’s first of this brand), although this was just a matter of becoming familiar with the CNC’s interface and where to access specific functions. He appreciates functions such as the capability to program operations based on one kinematic point/work coordinate system using the TNC 640 CNC, rather than programming with G54 or G55 G-code offsets. The shop uses GibbsCAM to develop part programs for this machine as it does with its other milling machines.

In fact, Gill notes that capabilities like these are why the Micro Pro is his preferred machine to program and operate.

Related Content

5-Axis Machining Center for Milling Diverse Materials

PMTS 2023: The Grob 6350 Generation 2 Universal Machining Center has the ability to rough and finish on the same machine to produce a complete part in one setup for increased productivity.

Read MoreUnattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

Read MoreOkuma Machine Lineup Features Intelligent Manufacturing Technology

IMTS 2024: Okuma’s booth features CNC machine tools, a CNC control, a line of automation systems, intelligent manufacturing technologies, customer services and more.

Read MoreKaast 5-Axis CNC VMC Offers Rigidity, Cutting Performance

The VMC includes a 30-tool magazine for flexible milling and drilling applications as a standard feature.

Read MoreRead Next

Automatically Optimize Your CNC Machining Feed Rates

New feed-rate-optimization technology can enable CAM programmers to reduce cycle times and increase tool life for milling and turning operations.

Read MoreHuman-Like Robot Automates Secondary Machining Operations

Two seven-axis robots enable two second-op mills to run lights out eight hours in the evenings to win 64 hours of unattended machining time per week for this Ventura, California, shop.

Read MoreCarving Out a Niche in CNC Plastics Machining

This Vermont shop focuses solely on machining plastics — some filled with abrasive glass — for a range of industries. That makes it stand apart from others, but means it also faces challenges that metal machining shops often don’t encounter.

Read More