Why Short Magazine Bar Loaders Are Efficient

So when are long bars and hydraulic magazine barfeeders justified? Typically, the best applications for long bar magazine feeders are found when production quantities are large (where the batch size exceeds 5,000) or when the workpiece is over 8 inches long and there are relatively few changeovers (one every 2 weeks or so). In most other cases, short barfeeders usually tend to be more efficient and a better investment. But let's analyze the reasons and find out why.

Most agree that modern automatic bar loading allows you to get a very good return on investment and high productivity from your CNC bar turning lathe. The remaining decision is the choice between running 10 or 12 foot long bars in long hydraulic magazine bar feeders, or running short bars, usually cut between 3 and 4 feet long, contained within the length of the lathe headstock.

The growth in the popularity of short bar loaders in the last 5 years, although impressive, does not necessarily make them universally applicable. Average lot size, material type, material diameter or profile, accuracy required, cutting speed, the ability to run unattended, and the investment amount are just some of the considerations that will determine the best solution for your specific needs.

So when are long bars and hydraulic magazine barfeeders justified? Typically, the best applications for long bar magazine feeders are found when production quantities are large (where the batch size exceeds 5,000) or when the workpiece is over 8 inches long and there are relatively few changeovers (one every 2 weeks or so). In most other cases, short barfeeders usually tend to be more efficient and a better investment. But let's analyze the reasons and find out why.

Spindle rpm. In the past 10 years the top spindle speed of most CNC lathes has increased significantly, and it is now common to exceed 6,000 rpm on a lathe with 2 ½ inch diameter bar capacity. There is no problem taking advantage of the increased speed and producing high precision parts with an excellent finish if you use small bar diameters of light material or short bars contained within the length of the lathe headstock running concentric with the spindle centerline. However, it becomes a huge problem as soon as you add bar weight and/or unbalance.

Material weight, unbalance and spindle load. The weight and the unbalance of the material grows with the length of the bar. The resulting effect on spindle load, part accuracy and surface finish is often underestimated. The problems and risks increase considerably with a longer bar.

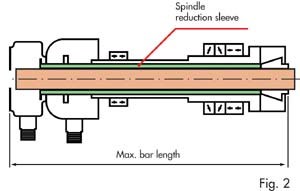

Guiding the material. When using short bars, the total length of the bar is supported concentrically on centerline by the spindle reduction sleeve or bushings, machined to match the outside diameter of round bars or across the corners of hex, square or other profiled bars. When using long bars, the material is generally not supported within the length of the lathe spindle, as the reduction sleeves are usually sized to fit the outside diameter of the barfeed pusher, not the diameter of the barstock. With long hydraulic magazine barfeeders, speed will be limited by such factors as barstock diameter and profile shape, the diameter of the barfeed guiding channel, weight and length of the bar. Even with the correct size guiding channel, pusher and other equipment, spindle speed is still limited by the capability of the hydraulic magazine barfeeder to control the long spinning bar, keep it on centerline over its entire length and keep vibration under control. The actual capability of the barfeed is generally less than that of the CNC lathe and modern cutting tools. This difference is especially significant when running hex, square or other profiles.

Material handling. Even if spindle speed and floor space are not major issues, the ease of handling short, lighter bars from storage through the shop to the lathe is a big advantage. This is especially an issue with bars 1 ½ inches in diameter and larger.

Spindle length. Depending on the manufacturer and type of lathe, the total length of the spindle—including the chuck or collet closer and hydraulic cylinder—is generally between 36 inches and 60 inches. Material must be purchased or cut to this required length or shorter.

Spindle extension. Often, when the total length of the spindle becomes shorter than 36 inches, the use of a spindle extension might be justified, the goal being to reduce the number of remnants and saw cuts. There are several solutions on the market to extend the spindle length, but beware, this is a very hot subject as these extensions often limit performance. The same safety requirements that apply to extensions also apply to single bar feeders or magazine bar feeders. A spindle extension only makes sense if perfect guiding of the bar can be guaranteed and any round or profiled bars can still be run at the maximum spindle speed.

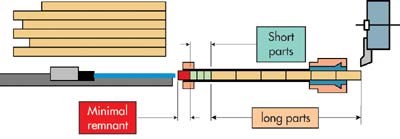

Bar end remnant. The front/forward ejection of any bar end remnant, together with the cost of material, has to be properly analyzed, especially when machining long parts. Depending on the lathe configuration and its chip conveyor, there may be difficulties due to the length or weight of the remnant damaging the chip conveyor. Modern "servo drive" bar loaders and lathe CNC controls with software can minimize the actual remnant length by allowing the user to machine both short and long parts from the same bar in one automatic cycle. Another alternative is to control the sawed bar length to equal some multiple of the workpiece length plus 2 inches for workholding, thus minimizing the length and weight of any remnant. With long hydraulic magazine barfeeds there will be fewer remnants, but each will be about 2 inches longer than the remnant due to its rear remnant ejection and the collet system that grips the back end of the bar.

Changeover. The changeover time, together with ease of changeover, are major issues where production batches drop below 2,000 pieces. If you have two or more changeovers a week, you need to carefully consider this comparison element.

If you compare the total changeover time between a long hydraulic magazine, including change of guiding channel, pusher and pusher end collet, against a modern short bar loader, you will easily gain 30 - 60 minutes each time. This savings is usually greater than the cost of any additional remnants.

Material preparation. Forget about the expensive bar end chamfering, pointing or turning required when using single bar feeders or long hydraulic magazines. There is no need to chamfer or make any other preparations with short Spacesaver barfeeders, just cut to length and deburr.

Ease of use. Another major advantage of a short barfeeder is its simplicity. There is no need for experienced or highly skilled operators to change over or run a Spacesaver style barfeed as there is with a long hydraulic magazine.

Increase productivity, reduce part cost. The productivity capabilities of short bar loaders are often underestimated.

Like most automation, bar feeds are designed to help a shop achieve better levels of productivity. Selecting the type and style of loader is an important consideration. With the advent of short bar feeders, shops have an additional choice to maximize efficient production of parts. Long or short, each has a place. The application calls the tune.

Related Content

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreChuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

Read More4 Bright Ideas for Effective Lights-Out Machining

Adopting lights-out machining involves considerations when a machine shop decides to move forward with the process. Here are some tips to a successful implementation.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.png;maxWidth=300;quality=90)