Exploring the Benefits of Reaming for Finishing Bores

How does reaming compare to single-point boring? A supplier of reaming tools compares these processes commonly used to finish bores and offers tips for those considering reaming.

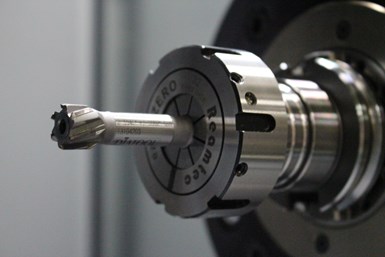

High-performance reamers have multiple cutting edges, which allow for higher feeds and speeds compared to single-point boring.

Reaming is a machining operation that shops might use to finish bores. Monaghan Tooling Group, which represents Diatool, a German company with more than 35 years of experience in the manufacturing and repair of multibladed reamers, suggests that reaming can offer advantages in terms of speed, tool life and surface finish quality when compared to other processes such as single-point boring.

But, what is reaming? Reaming is a process of finishing a bore by way of removing a small amount of material with a cutter. It is a combination of cutting and cold working materials. Reamers are designed to provide size control and surface finish, but do not provide true position. The condition and location of the pre-reamed bore are critical as a reamer will generally follow it.

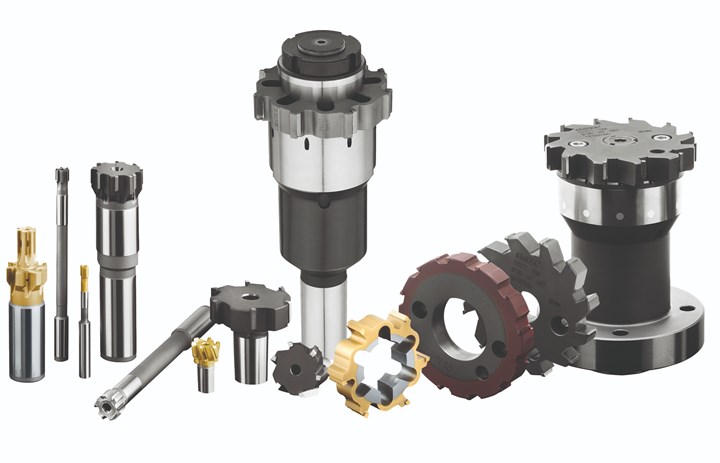

Monaghan Tooling Group says what it refers to as its high-performance reaming tools differ from conventional reaming tools in that they feature unequal flute spacing. This is said to create precisely round holes and a higher surface quality compared to conventional reamers with equal flute spacing. The company says these multi-edge reamers can also be run at higher speeds and feeds while achieving excellent hole quality, close dimensional tolerance and quality surface finish. Its reamers can be tipped with carbide, cermet or polycrystalline diamond (PCD). The use of modern, thin-film physical vapor deposition (PVD) coatings can also improve performance, especially in materials such as gray cast iron, stainless steel and many high-temperature super alloys. According to the company, these reaming tools offer four primary benefits:

• Higher feeds and speeds. High-performance reamers have multiple cutting edges, which allow for higher feeds and speeds compared to single-point boring, resulting in reduced cycle time. High-performance reamers feature from four to 16 teeth compared to one insert in a single-point boring tool — the increase in feed rate can be four to 16 times faster. Single-point boring is used to achieve the correct size and finish in a bore, but, with only one cutting edge doing the work, it is inherently slower.

• Fast setups. With high-performance reaming, setting the reamer is a straightforward process as the first bore is a good bore. There is no need to adjust the diameter because the tool is ground to the correct diameter. In addition, reaming is a stable and secure process that does not require the same level of adjusting as single-point boring.

• Reducing scrap. Minimizing scrap is especially important when working with very expensive materials. In the aerospace industry, for example, manufacturers often produce lower quantities of parts from Inconel, titanium and other high-cost materials. For these manufacturers, using a high-performance reamer can provide consistent hole sizes throughout the life of the tool and significantly lower scrap ratios.

Expandable and Solid Reamers

High-performance reamers come in two general configurations: expandable and solid (nonexpandable). Because reamers do wear with use, an expandable reamer gives the user the ability to expand the reamer within the tolerance field of the bore to extend tool life. An expandable reamer is targeted to the mean of the bore diameter. The expansion can be done multiple times until the wear reaches the point in which the surface finish is no longer acceptable. At this point, the reamer can be retipped to as-new condition.

Unequal flute spacing is said to create precisely round holes and a higher surface quality compared to conventional reamers with equal flute spacing.

The diameter of a solid reamer is targeted to two-thirds the tolerance. This is to allow for more wear, as this type of reamer cannot be expanded. Once the reamer has reached its tool life, either for size or surface finish, it can also be retipped.

To suit specific application requirements or customer needs, expandable and solid reamers can be targeted almost anywhere within the diameter tolerance field. Two things to consider when deciding between expandable and nonexpandable reamers are bore diameter tolerance and surface finish requirement. Tight-tolerance bores with relatively rough surface finish callouts are more suited to expandable reamers because the expandable reamers have the capability of expansion to gain tool life. A more open-tolerance bore with a high surface finish callout is more suitable to a nonexpandable reamer because, generally, the surface finish will fall out of specification before the diameter.

Reamers can be tipped with carbide, cermet or polycrystalline diamond (PCD). The use of modern, thin-film physical vapor deposition (PVD) coatings can also improve performance.

Here are a few considerations for shops considering reaming that Monaghan Tooling Group suggests:

• High-performance reamers can be manufactured for flood or through-tool coolant delivery.

• A left-hand helix is common for high-speed reaming of through holes. A straight flute can be used for through or blind holes.

• Factory retipping of high-performance reamers makes them even more practical and economical. Reconditioned tools have the same tool life as new tools. A reamer can be retipped multiple times as long as the steel body is still in good condition. Depending on reamer diameter and application, it is possible for a high-performance reamer to be reconditioned 10 or more times.

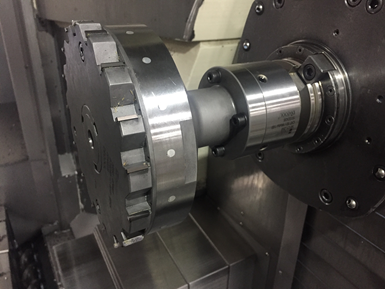

• To optimize tool holding, compensation holders may be required to correct for runout and misalignment.

• Because high-performance reaming is both a cutting and cold-working process, it is especially important to use a high-quality coolant to achieve bore quality and tool life. Consider a metalworking fluid with high lubricity properties for reaming.

Related Content

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreThe Value of Tool Monitoring on Rotary Transfer Machines

By using a tool monitoring system, shops can save costs associated with machine maintenance and downtime for tool changes while increasing cutting performance.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreThe Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MoreRead Next

A Guide to Insert Coating Processes and Materials

Few materials have had a greater impact on our economy and industrialized culture than cemented tungsten carbide.

Read MoreRound Versus Indexable Tools: From the History to the Latest Developments

Time has allowed great improvements to the durability and performance of cutting tools. The materials used have impacted round and indexable tools in different ways.

Read MoreMonaghan Tooling’s Top Speed Ring Allows 70% Higher Feed Rates

Monaghan Tooling Group introduces its Top Speed Ring, a reamer that allows higher feed rates.

Read More

.jpg;maxWidth=300;quality=90)