Monaghan Tooling’s Top Speed Ring Allows 70% Higher Feed Rates

Monaghan Tooling Group introduces its Top Speed Ring, a reamer that allows higher feed rates.

Monaghan Tooling Group’s Top Speed Ring is a reamer that allows up to 70% higher feed rates than traditional cutting rings, according to the company. These modular Top Speed Rings require no setting.

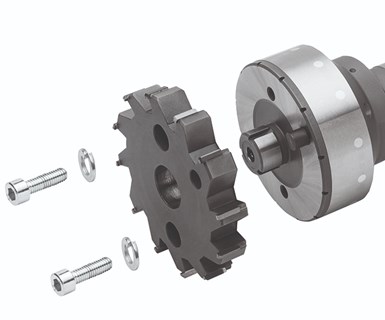

Monaghan Tooling's Top Speed Ring.

They have a diameter range from 50,600 mm–225,000 mm (1.9921”-8.8583”). Four extra teeth compared with expandable rings are designed to allow for faster cutting with better surface finishes and roundness. Solid, straight or left-hand fluted designs ensure stoutness throughout its long service life, the company says.

Different cutting materials and coatings are available to ream a variety of part materials, special geometries upon request. Holders come with internal coolant as standard. The Top Speed Ring holders are made with either cylindrical shanks or module connections for runout compensation. The Top Speed Ring can be repaired/re-tipped and achieve the same tool life as new reamers, making them efficient and cost-effective, the company says. They are especially useful for high speed reaming applications, long production runs, large hole reaming and whenever precise, repeatable reaming is required.

Related Content

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Repeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

-

Boring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

.png;maxWidth=300;quality=90)