Multitasking Takes a Turn

Turn-mill machines are known for their capabilities in single-setup part production. Here are two very different examples of shops that are using multitasking to their advantage in medical machining.

Turn-mill machines are capable of both rotating-workpiece operations (turning) and rotating-tool operations such as milling and cross-drilling. Typically, the machine is recognizable as a horizontal or vertical lathe, with spindles for milling and drilling available at some or all of the tool positions.

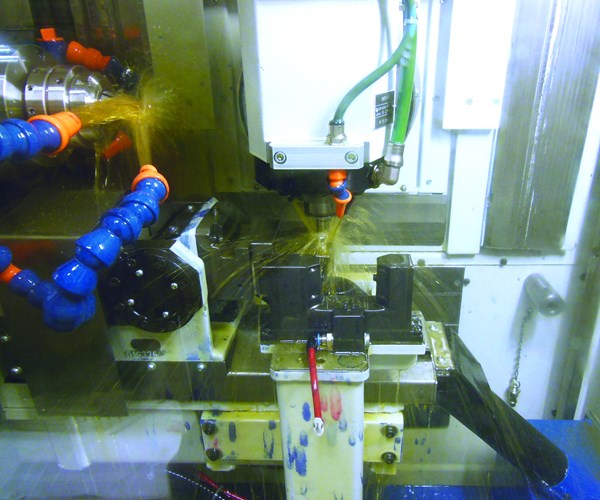

Willemin-Macodel, Inc. offers a line of multitasking machines designed as five-axis bar-fed milling machines, but they include 6,000-rpm turning capabilities on the A axis and tool magazines ranging in capacity from 24 to 72 to accommodate both milling spindles and turning toolholders (a certain number of which can lock the tool, oriented at a specific angle to cut as the spindle turns like a lathe).

In “Applying Multitasking’s Versatility,” we visit a shop that has a few of these machines (408MT models) in place to handle parts that are more milling heavy yet require as much as 20 percent of the part to be turned. The machines allow the company to drop its complex medical parts complete in a single setup.

In our latest issue, we visit a shop specializing in 3D printed parts but also taking advantage of the Willemin design. “First-Class Manufacturing with Additive” discusses how the shop is using the 508MT model to finish its 3D printed medical components such as acetabular cups for hip replacement as well as other implant parts.

Related Content

-

5-Axis Machining Centers Transform Medical Swiss Shop

Traditionally a Swiss machine shop, Swiss Precision Machining Inc. discovers a five-axis machining center that has led the company to substantial growth. (Includes video.)

-

Video Tech Brief: Twin-Turret, Twin-Spindle Lathe Machining

This machine model features roller linear ways to accommodate low-frequency vibration technology to minimize chip size.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

.jpg;maxWidth=300;quality=90)