Robotic Efficiency

Shops implement automation for different reasons. Read about one that used robotics to improve production by almost 90 percent while effectively redistributing labor on the shop floor.

Shop owners have varying reasons for pursuing automation on their shop floors. Sometimes they’re after better machine usage and higher production capacity. Others may be compensating for a shortage of labor. Still others may have a need for flexibility in adjusting to changing production requirements. One North Carolina shop incorporated robotic automation as a progressive move to remain competitive and improve workflow.

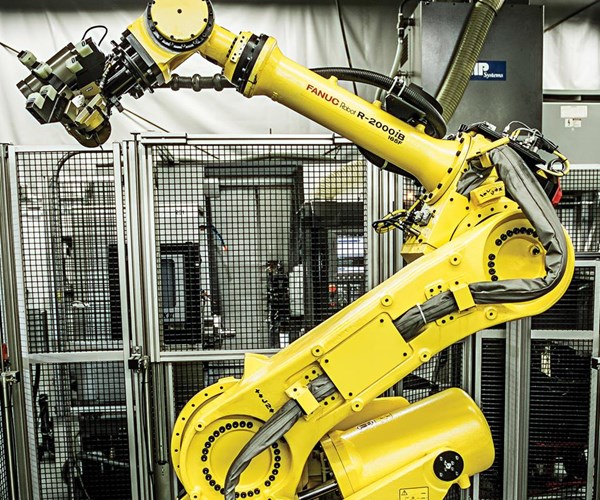

Read “Reducing Production Times with Robotic Automation” to learn how Northeast Tool improved production by almost 90 percent. The company condensed the functions of three CNC lathes, two milling operations, polishing, washing and inspections after each operation into a single cell consisting of one robot and two lathes. Instead of requiring time from 15 people, the new setup is now manned by a single operator.

Related Content

-

Automation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Unattended Production Takes More Than the Most Capable CNC Machine

Process planning and reliable peripherals are key to successful lights-out manufacturing.

.jpg;maxWidth=300;quality=90)