Shops Continue to Expand Capabilities

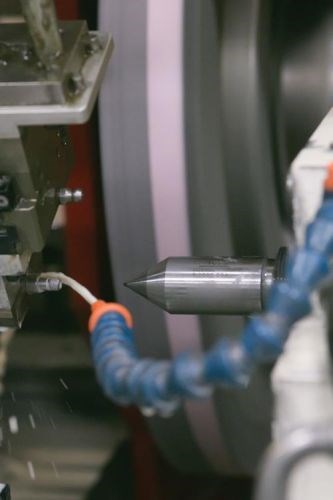

In our August issue we visited a shop that has added grinding machines to its Swiss operations to further facilitate its production processes. What’s cooler is the automation added to these grinding operations.

Some shops like to remain focused on a single niche, such as Swiss turning, and farm work out when necessary to fill customer needs. Others find it more effective to broaden their scope as customer demands require additional capabilities.

In our August issue we visited a shop that has added grinding machines to its Swiss operations to further facilitate its production processes. What’s cooler is the automation added to these grinding operations to allow them to keep pace with the lights-out functionality of the Swiss machines. Read “Shop Combines Automated Grinding and Swiss Turning” for more information.

Grinding seems to collaborate well with other high production turning operations. Emag offers a machine that handles both. We’ve covered this machine in the past. Check it out in “Grinding in the Multitasking Mix.”

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Inside the Premium Machine Shop Making Fasteners

AMPG can’t help but take risks — its management doesn’t know how to run machines. But these risks have enabled it to become a runaway success in its market.

-

Replace Repetitive Measurement With DIY Robotic Automation

After minimal training, a shop can learn how to use this robotic inspection system configured for a shopfloor application to supersede repetitive, time-consuming, high-mix gaging processes. It can then be redeployed for another application somewhere else in the facility.