Adaptix Soft Jaw Provides One-Size-Fits-All Workholding Process

Adaptable soft jaw is designed to streamline CNC machining process and provide a one-size-fits-all way to enhance workholding efficiency.

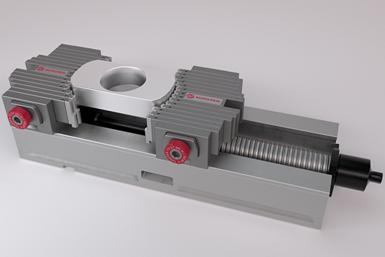

Adaptix Soft Jaw

Norgren’s Adaptix Soft Jaw uses adjustable fingers and interchangeable tips to grip a wide variety of parts or workpieces during the computer numerical control (CNC) machining process. It was specially engineered to be a one-size-fits-all alternative to standard, single-application aluminum soft jaws.

The company says single-application soft jaws require a significant amount of time, skill and raw material to construct, even before a single part is milled. The Soft Jaw is designed to solve several machining problems with just one tool. It is said to grip nearly any part with comparable repeatability and clamping force as single-application soft jaws, thereby enhancing CNC machining workflow efficiency.

The Soft Jaw’s adjustable fingers and interchangeable tips are made out of a variety of different materials to match the milling needs of a particular part. The fingers easily mold into place to conform to the shape of the target part and then lock in place, the company says. This configuration process takes minutes, instead of hours (on average) with traditional soft jaws. The soft jaw fits directly onto a vise, and is currently compatible with Kurt and Schunk brand vises, with other vise compatibility planned in the near future.

Related Content

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

-

The Value of Swiss-Types Milling Rectangular Medical Parts

High-speed spindle technology was key to effective milling of small cardiac monitoring components complete on a CNC sliding-headstock machine platform instead of running them across two mills.

.png;maxWidth=970;quality=90)

.png;maxWidth=300;quality=90)