Allied Machine Offers High-Penetration Drill System

T-A Pro drill designed to extend tool life, create consistent quality holes and provide better chip evacuation.

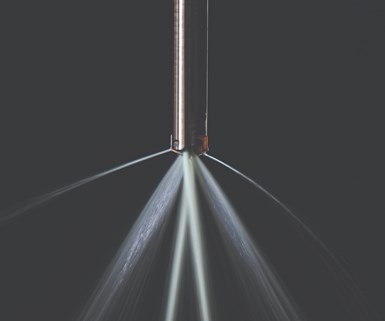

Allied Machine and Engineering’s T-A Pro drilling system combines material-specific insert geometries, redesigned drill body and proprietary coolant-through system for high-penetration drilling. According to the company, this enables penetration rates which run at speeds nearly 30% faster than other high-performance drills.

The company says that the coolant outlets are designed to direct maximum flow to the cutting edge, providing quick heat extraction where it is most critical, even at significantly higher speeds. Material-specific insert geometries are designed for effective chip formation, while the drill body incorporates straight flutes redesigned for maximum coolant flow and high rigidity. These design elements combine to extend tool life, create consistent quality holes and provide good chip evacuation.

The T-A Pro drilling system is available in diameters ranging from 0.4370" to 1.882" (11.1mm – 47.80mm) and is said to be well-suited for holes ranging in stub, 3×D, 5×D, 7×D, 10×D, 12×D and 15×D depths. The drill comes in both imperial and metric shanks, with flat and cylindrical variants. The initial carbide insert geometries will work with steel (P) with AM300 coating; cast iron (K) with TiAlN coating; and nonferrous (N) with TiCN coating.

Related Content

-

The Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

-

Producing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

.png;maxWidth=300;quality=90)