Emuge Thread Ring Gages Recognize Size, Form Deviations

The company says the expanded line of gaging solutions is suited for challenging thread gaging applications.

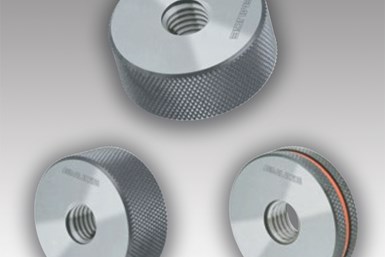

Emuge-Franken’s line of thread ring gages includes UNC and UNF Go and No-Go ring gages, in addition to metric and metric fine Go and No-Go ring gages for a total of 152 new gages. Photo Credit: Emuge-Franken

Emuge-Franken has expanded its thread gaging solutions to include a line of thread ring gages, which includes UNC and UNF go and no-go ring gages, in addition to metric and metric fine go and no-go ring gages for a total of 152 new gages. Thread gages can be used to safely and economically control the production process, enabling users to quickly recognize size and form deviations, and weakened or unfit threads, the company says.

The ring gages are designed to complement the company’s line of fixed limit thread gages, consisting of go/ no-go plug gages and thread depth plug gages which inspect the pitch diameter and functional thread for internal threaded components.

These gages are manufactured with hardened tool steel for exceptional durability and feature a fully knurled circumference for maximum gripping ability and safety, the company says. No-go gages are clearly marked with a red ring. UNC and UNF gages have a 2A tolerance.

UNC gages are available in 19 sizes from #2-56 to 2-4 ½ and UNF gages are available in 19 sizes from #0-80 to 1 ½-12. Metric and metric fine gages have a 6-g tolerance. Metric gages are available in 19 sizes from M2×0.4 to M68×6; and metric fine gages are available in 19 sizes from M8×1 to M48×1. Additional sizes are also available upon request.

All gage sizes are furnished with a short form gage certificate at no additional charge. Upon request, long form certificates are also available.

Related Content

-

Addressing Machining’s Necessary Evil

Many view quality control as such, but integrating new measurement technologies and approaches can ultimately minimize QC’s impact on throughput and a company’s bottom line.

-

Streamlining Part Measurement, Data Collection Processes

When collecting measurement data automatically with a wireless data collection system, manual errors can be eliminated ensuring data accuracy and traceability.

-

Precision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.