Heidenhain’s Encoders Provide Multidimensional Measurement

Using multiple reader heads enables the detection of deflections, thereby enabling necessary compensation at the inception to provide consistent quality.

Heidenhain’s Multi Degrees-of-Freedom (MULTI-DOF) encoders are designed to offer machine manufacturers a better way to implement metrology designs.

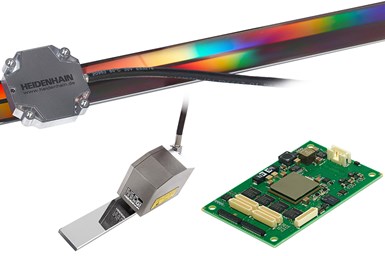

Heidenhain’s Multi Degrees-of-Freedom (Multi-DOF) encoders are said to offer machine manufacturers a better way to implement metrology designs to obtain multiple measurements simultaneously and facilitate correcting deviations on the fly, thus enabling consistent quality. The Multi-DOF encoders include the LIP 6031 Dplus, GAP 1081 and MKV 1/9x30.

Traditionally, an encoder is only able to measure deviations along a single axis. Although these can be corrected via some controllers, they can still be blind to common but unavoidable effects of guideway error or thermal linear expansion (to name a few) which would cause deflection along multiple axes. The Multi-DOF encoders use multiple reader heads which enable detection of deflections, thereby enabling necessary compensation at the inception and ensuring the integrity of the machine. The company says users of these high-accuracy Multi-DOF encoders can expect high reproducibility and consistent quality in their systems.

The LIP 6031 Dplus is based on the standard Heidenhain LIP 6000 linear encoder. In essence, two LIP 6000 encoders have been integrated into a single device to read two graduation tracks on a measuring scale angled at ±45 degrees relative to each other, thereby making it possible to measure in both the main direction and orthogonally to the main direction at a measuring length of ±2 mm.

The GAP 1081 is the first gap encoder from Heidenhain. Rather than using interferometry for gap measurement, it utilizes Heidenhain’s own encoder technology, enabling measurement of the gap between a mirrored scale and the scanning head. Out-of-plane measurement is thus very easy to implement in a metrology design, the company says.

Heidenhain’s MKV 1/9x30 enables the bus capabilities of EnDat 3 interface by reading the position values of up to four 1 VPP scanning heads. This is useful for multidimentional encoders where the readings from each head can be calculated and sent to the customer’s controller on just a single cable. This enables a reduction in the number required cables and prevents the controller from needing to make such calculations.

Related Content

-

Zoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

-

Automated Inspection Transforms Medical Manufacturer’s Quality Control

Manual steps for part inspection have been eliminated with a new CMM process using more advanced software and strategies such as using a combined scanning/touch-trigger probe.

-

Precision Machining Technology Review: December 2023

Production Machining’s December 2023 technology showcase includes some of the latest technology from Sandvik Coromant, Nikon Metrology, The L.S. Starrett Co., Walter USA, Kennametal and SolidCAM.

.jpg;maxWidth=300;quality=90)