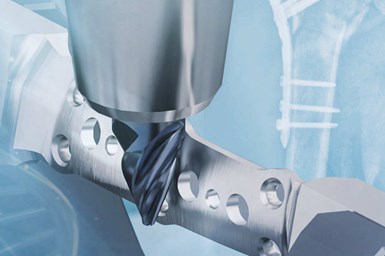

Inovatools’ Solid-Carbide Cutters Designed for Medical Components

Inomed tools machine medical components made from hard-to-machine materials.

Inovatools’ Inomed line offers a selection of solid-carbide premium tools and customized special tools for medical components, including mills, drills, engravers, deburrers and special tools. According to the company, the line is designed for complex drilling and milling tasks with micron-level precision, and precise drilling for diameters between 0.1 mm and 20.0 mm on medical components made from titanium, chromium cobalt and INOX.

According to the company, the solid-carbide engraving and deburring tools are suited to microchamfering and deburring difficult materials such as titanium and stainless steel as well as machining areas that are hard to reach. The solid-carbide drills are said to offer precise drilling for titanium and other noncorrosive and hard-to-machine materials. The solid-carbide INOX mills, mini mills, reamers and drills are designed for machining titanium bone plates, which can have difficult-to-access geometries.

The company says the Inovatools Curvemax enables shorter production times because its curve segment mill features special geometries to permit larger path distances and line jumps during prefinishing and finishing. Although the working radius is larger than that of a traditional full-radius mill, the tool still has the same diameter, leading to reduced process times. The larger and flatter overlap is said to reduce roughness and ensure surface finishes that are better than those created by traditional full-radius mills. The Curvemax mills can also be used to create undercuts, freeform surfaces and variable setting angles. Complex contours can be prefinished and finished, even on narrow inside radii.

Related Content

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

New Cutting Tool Technology Discovered at Paul Horn Open House

During a tour of the company’s campus in Tubingen, Germany, I and more than 3,000+ others were introduced to a number of new advances the company has made in cutting tool technology particularly as it relates to the medical industry.

.png;maxWidth=300;quality=90)