Lach Diamond Inc. Engraving Tools Provide Wear Resistance

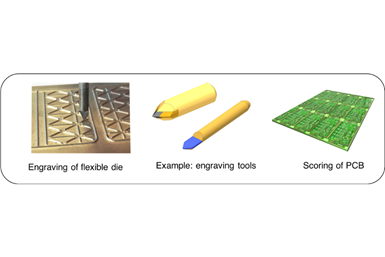

PCD- or CBN-tipped engraving tools enable competitive machining strategies for processing magnetic flexible dies as well as cutting rotors made of high-quality, challenging materials.

Lach Diamond Inc.’s PCD- and CBN-tipped engraving tools are designed to provide a highly precise, wear-resistant solution for the stamping technology sector, as well as the packaging and printing industry.

According to the company, engraving tools tipped with PCD or CBN cutting materials enable competitive machining strategies for processing magnetic flexible dies as well as cutting rotors made of high-quality, challenging materials. Other applications include scoring of PCB and engraving of high-tensile, wear-resistant materials.

Lach Diamond offers its PCD- and CBN-tipped engraving tools in standard or customized dimensions, as semi-finished or finished (including side-cut) and with highest reachable surface qualities.

Related Content

-

Shop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

-

Starting Small with Automation

Quick-change workholding and flexible robotic automation started this small shop on the path to success.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

.png;maxWidth=300;quality=90)