Sandvik Coromant Cutters Complete Gears in Single Setups

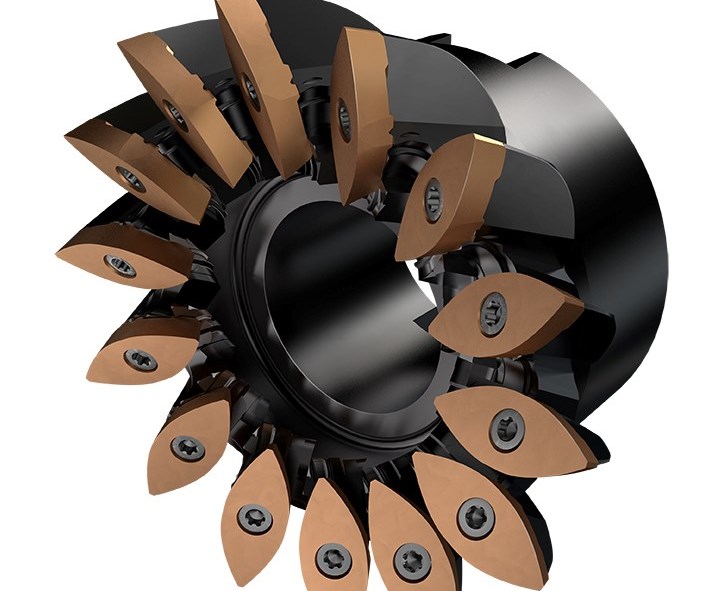

A power skiving solution composed of CoroMill 178 and CoroMill 180 cutters from Sandvik Coromant helps automotive manufacturers complete gear and spline components in one set-up on a multi-task machine or machining center.

The power skiving solution from Sandvik Coromant includes a solid bore, solid shank and indexable cutters. These tools are said to offer high tool accuracy with regard to run-out and pitch. Reconditioning can be performed as many as 10 times depending on the quality of the tool. The cutters feature a positive rake angle for light cutting action and the potential for dry machining.

According to the company, the power skiving cutters provide both high output and an optimized finishing profile. The tools are designed to meet customer specification and are said to be as much as 15x faster than shaping and more flexible than broaching. Applications include internal and external gears and splines, in addition to cylindrical spur and helical gears for automotive transmissions, and variety of other gears, coupling components, splines, shafts, synchronization rings and CV joint parts.

Related Content

-

Producing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

-

Making Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

-

Parting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

.png;maxWidth=300;quality=90)