TDM System's Global Line 2019 Aims to Meet Shops' Software Needs

TDM Shopfloor Manager enables comprehensive workflow management, incorporating booking functions and interfaces for crib systems, presetting devices and machines as well as for high-level systems such as MES, FMS and ERP.

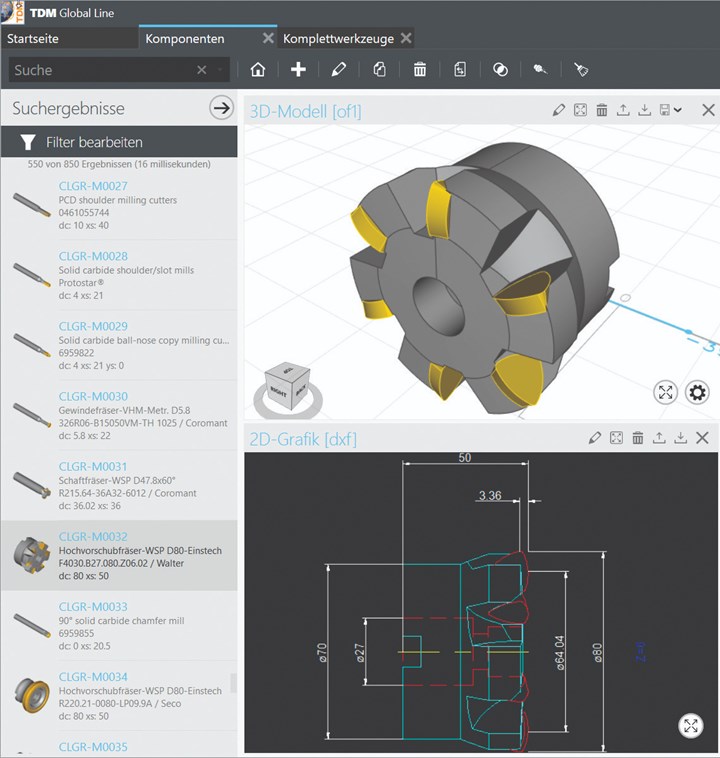

TDM System’s Global Line 2019 includes its core solution software, comprised of TDM Shopfloor Manager, TDM Production Document Management, Graphic Functions and TDM Webcatalog.

TDM Shopfloor Manager enables comprehensive workflow management, incorporating booking functions and interfaces for crib systems, presetting devices and machines as well as for high-level systems such as MES, FMS and ERP. Users can create multiple shopfloor configurations to depict workflows in various production areas. Individual status management is a feature that enables the user to define the tool status themselves within the workflow.

TDM Production Document Management is a new module that enables users to assign documents to the production resources, via a drag-and-drop function, either in the form of a link to the actual saved location or as a copy on the TDM Global Line server.

With Graphics Functions, the user can generate rotation contours from 2D graphics using the Tool Contour Generator, with the aid of an intuitive user navigation system. In combination with the TDM 3D-Rotation Generator, simulation-ready 3D models can be generated for realistic collision-checking in CAM systems.

After registering with TDM Systems, the TDM Webcatalog provides cloud-based tool catalogs that obtain up-to-date verified tool data from leading manufacturers, the company says.

TDM Global Line 2019 features a hybrid mode, which enables the software to work in conjunction with other programs. Global Line modules such as the Shopfloor Manager can be used in combination with the TDM 2019 version. Access to the TDM Webcatalog is also possible for the current version. Everyday work can also be facilitated via the Multiple Plant Management system, which assigns equipment with improved precision.

Related Content

-

Lone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

-

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

-

Mastercam Software Improves Programming Flexibility

IMTS 2024: Mastercam introduces Mastercam 2025, with features including Mastercam Deburr for automated edge finishing, finish passes, mill-turn support for Y-axis turning and automatic license update notifications.

.jpg;maxWidth=300;quality=90)