Tungaloy Expands ISO-EcoTurn Insert Geometries

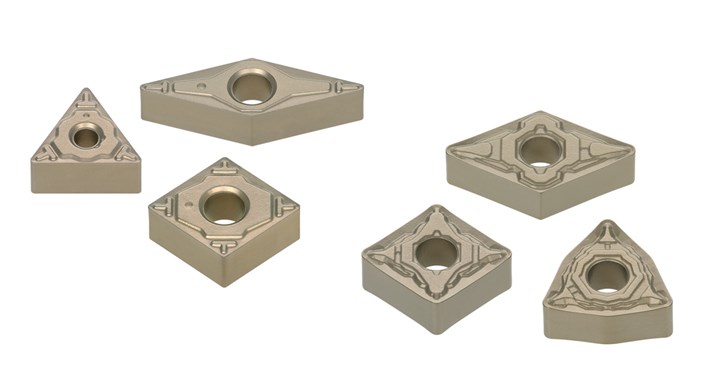

Tungaloy further expands its ISO-EcoTurn line of economical turning inserts to include new geometries and nose radius size for precision finishing of steel.

Tungaloy further expands its ISO-EcoTurn line of economical turning inserts to include new geometries and nose radius size for precision finishing of steel.

ISO-EcoTurn inserts

ISO-EcoTurn inserts, while downsized for tool economy, incorporate the identical chipbreaker geometry and thickness of regular-sized inserts to maintain the same cutting performance at a depth of cut up to 3.0 mm (0.12"). Typically, when an insert is downsized, the thickness of the insert is reduced as well. However, these inserts preserve the thickness of standard inserts in order to maintain fracture resistance. Because of reduced volume per insert, these inserts decrease cost per insert on the production line without compromising insert performance.

The insert lines include -TSF geometry for finishing applications, -TF geometry for precision finishing, as well as 0.2-mm nose radius size for corner accuracy.

The inserts are offered in T9215 and T9225 grades, the company’s latest CVD grade series designed to provide exceptional wear resistance and prolonged tool life in steel turning, the company says.

Related Content

-

Repeatability and Rigidity Are Key for Quick-Change Swiss Tooling

A rotary wedge clamping system is said to enable this two-piece, modular tooling system for Swiss-types to offer the performance of a solid tool.

-

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

-

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

.png;maxWidth=300;quality=90)