Metalworking Fluids

A Guide to Metalworking Fluids

The oils, coolants and lubricants used in metalworking shops are often overlooked as an opportunity to improve process efficiencies.

Read MoreMaximize Coolant Life with Efficient Tramp Oil Removal

Increased demands for high surface finish and close part tolerance create a greater need for manufacturers to purify coolants that are constantly being cycled through precision machinery.

Read MoreWater-Glycol Hydraulic Fluid Resists Fire

Quaker Chemical’s Quintolubric 702-46 RD fire-resistant hydraulic fluid is a water-glycol formulation designed to increase safety, reduce maintenance and extend product life.

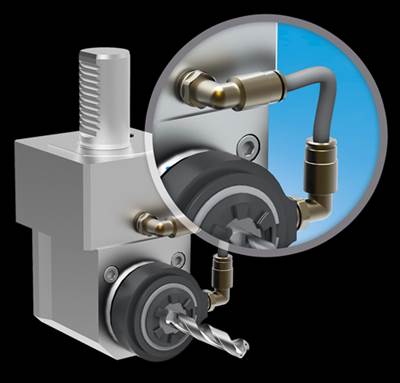

Read MoreExternal-Coolant Live Tooling Heads Get an Upgrade

One of the most important aspects of effective coolant usage is precise delivery to where it is needed in the cut.

Read MoreEfficient Use of Metalworking Fluids

As shops continue to reach for new ways to achieve higher efficiencies, they commonly turn to improved processes, new equipment and automation. But one point of attack—more effective use of metalworking fluids—often goes unaddressed.

Read MoreThe Changing Role of Metalworking Fluids

Every aspect of the metalworking process is under scrutiny to reduce costs and improve efficiencies, including the use of metalworking fluids.

Read MoreShopfloor Data and the Future of Manufacturing

Redundancy is far too common in many areas of life. Standardized processes that streamline production might be the perfect solution.

Read MoreTooling Tips for Exotics

While exotic materials typically provide improved wear characteristics and better service life in the final product, they can present particular challenges during machining.

Read MoreConsiderations for Machining Exotics

In manufacturing, the term “exotic” is used to describe materials that display excellent wear characteristics, durability and service life in high heat, extreme cold or corrosive environments.

Read MoreMagnetic Filtration Leads to Premier Finish

Magnetic filtration can be used in almost any environment where ferrous and paramagnetic contamination of a liquid is a problem.

Read More

.jpg;maxWidth=300;quality=90)