Software

Index Provides another Approach to Machine Control

Now available on all Index machines, this control is designed to put all necessary production information at the operator's fingertips.

Read MoreHandling Machining Complexity with CAM

With the increase in demand for closer tolerances on difficult-to-machine parts, shops look to improve efficiency through simplified processes.

Read MoreMoving Forward with Self-Directed Work Teams

We all deal with change in different ways. It’s critical to first, recognize, and next, do something constructive about it. The Ohio shop is well on its way on both fronts.

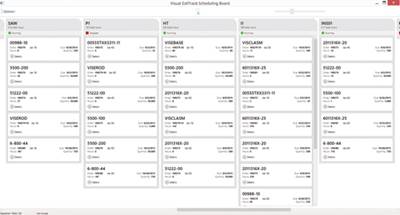

Read MoreScheduling Board Software Offers Touchscreen Interface

Henning Software’s new Visual EstiTrack Touch Scheduling Board software product incorporates a touchscreen interface that enables users to drag-and-drop scheduled shop order operations within and between work centers.

Read MoreCAM System Aids with Productivity and Simplifies Complex Parts

In the case of Webber Metal Products, upgrading the CAM system was all it needed in order to increase productivity and simplify complex part production.

Read MoreImprove Productivity with Digital Tooling Data

This system seamlessly interfaces cloud-enabled digital tooling data and intelligence with production, inventory, and e-commerce to optimize shop productivity.

Read MoreERP Software Assists Companies with Day-to-Day Operations

The characteristics that make a manufacturing company great are not only the quality of the products that are produced on a shop floor, but also how quickly these products are turned around to the customers.

Read MoreTool Monitoring for Complex Machining

One of the biggest challenges to tool monitoring on a multitasking machine is coping with simultaneous cutting operations. Caron Engineering (Wells, Maine) designed a system to meet this challenge.

Read MoreMultitasking Goes Vertical

This article looks at part processing and CNC programming considerations for vertical multitasking applications.

Read MoreSmooth Evolution of Machine Tool Control

Many traditional turning shops are expanding their capabilities to meet other machining requirements. Multitasking machines have helped these shops to naturally transition into smaller lot sizes and highly complex parts.

Read More

.jpg;maxWidth=300;quality=90)