Tooling

Large Diameter BTA Drilling Machine With 3-Axis Capability

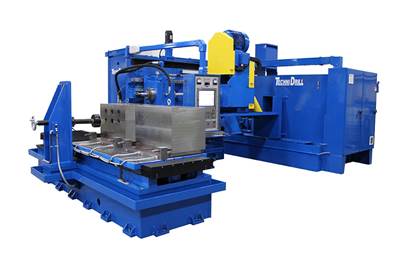

IMTS 2022: The TechniDrill TBTA-3A-6 can drill a 6-inch diameter hole from solid in a single pass and has 3-axis capability.

Read MoreIscar Neo Swiss Quick-Change Toolholders for Swiss-Types

IMTS 2022: Neo Swiss modular quickchange tooling line for Swiss-types feature a rotary wedge mechanical design for clamping rigidity and accuracy.

Read MoreHorn Supermini Set Offers Greater Holding Force

The Supermini toolholder system offers clamping carried out via a clamping wedge on the face.

Read MoreCutting Tool Insert Options for Turning HRSA Materials

Consideration of the types of tools used to turn heat-resistant super alloys commonly used for aerospace components is a necessary part of developing an effective machining process for those materials.

Read MoreCBN-Tipped Tools Optimized for Ferrous Metals, Hardened Steels

Carbon-tipped tools are said to last much longer than carbide tools and significantly reduce the price per hole.

Read MoreMini Clamping Device Changeover System Provides Actuation With One Screw

IMTS22: The clamping device is said to enable changeovers in less than one minute.

Read MoreGoeltenbodt Pre-Settable, Quick-Changeable Tooling System for Swiss-Type Lathes

IMTS 2022: The company says the system can provide quick and easy tool changeovers and is pre-settable off the machine with repeatability of .0004″.

Read MoreCeratizit EcoCut Multifunctional Tools for Drilling, Turning

IMTS 2022: The company says the tools can reduce setup time and increase productivity, and are designed to handle up to four different machining processes with just one tool.

Read MoreEmuge Thread Mills, Gages for Safety-Critical Applications

These tools are designed to increase tool life and reduce cycle times.

Read MoreWalter’s Drilling Grade for Drilling Aluminum

This grade is designed to enable reliable chip removal due to its smooth surface with a reduced tendency toward adhesion and buildup on the cutting edge, thereby increasing process reliability and wear resistance.

Read More

.png;maxWidth=300;quality=90)