Tooling

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

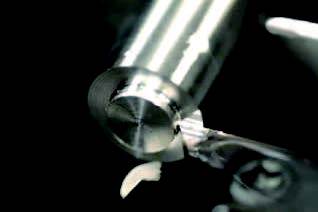

WatchAddressing Micro-Boring Challenges

This boring bar/tool holding system for Swiss-type lathes is said to offer high rigidity and positioning repeatability. In addition, the boring bars can be changed out using no hand tools.

WatchParting Off: The Case for Standardizing on Sawing

The value of rotary saw cutting for parting off operations could boil down to simple economics paired with process efficiency gains.

Read MoreTungaloy Modular Turning System Provides High Repeatability

The ModuMiniTurn tool system incorporates a specialized coupling mechanism between the modular head and tool shank.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreWalter Indexable Drill Inserts Provide High Wear Resistance

The WNN15 drilling grade features a hard substrate, which provides high cutting-edge strength and sharpness on indexable inserts.

Read MoreSMW Autoblok Vise System Provides Omnidirectional Clamping

The Plus5 V5 Zero Point Vise system interfaces with all industry-standard products using 52 mm or 96 mm pin spacing, enabling it to readily become part of existing workholding systems.

Read MoreThe Ins and Outs of Inserts

Understanding how inserts are made provides valuable insight into how their performance can be optimized.

Read MorePrecision Machining Technology Review: January 2024

Production Machining’s January 2024 technology showcase includes some of the latest technology from Monaghan Tooling Group, Okuma America, Tungaloy, Cortec Corp., Fixtureworks and T.J Davies Co. Inc.

Read MoreTungaloy Fine-Boring System Increases Machine Utilization

The latest KKH cartridge modules for the SwissBore digital fine boring tool system is designed to provide maximum machine utilizations with minimum measuring, setup and tool changing time.

Read More