Tooling

Horn Tool Configurator Shortens Lead Times

The HTC system enables quotations to be generated within one working day, with technical drawings available the next working day.

Read MoreKyocera Precision Tools' Coated Carbide Optimizes Turning

The CA115P/CA125 series is designed to provide extended tool life and superior performance in a variety of machining scenarios.

Read MoreBig Daishowa Enhances Boring Tools With Vibration Damping

Smart Damper technology shortens the distance from the damping mechanism to the cutting edge, which is the source of vibration.

Read MorePrecision Machining Technology Review October 2023

Production Machining’s October 2023 technology showcase includes some of the latest technology from Tungaloy-NTK America Inc., Renishaw, Walter USA, Seco Tools and Haimer USA.

Read MoreTungaloy Grooving Toolholders Provide Stable Turning

TungHeavyGroove includes an enhanced insert clamping design for maximum tool rigidity.

Read MoreSandvik Coromant Drill Provides High Hole Integrity

CoroDrill 860 solid carbide drill is optimized for drilling in nickel-based, HRSA materials.

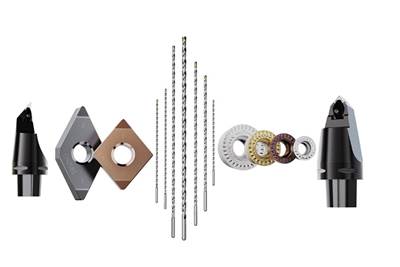

Read MoreSeco Tooling Lineup Promotes Optimized Part Processing

The company’s expanded tooling lineup is aimed at applications ranging from general ISO turning to high-volume hard turning and deep-hole drilling.

Read MoreTungaloy-NTK Swiss Turning System Provides High Repeatability

The ModuMiniTurn modular turning tool system provides exceptional repeating accuracy for the cutting point when swapping out modular heads for new inserts.

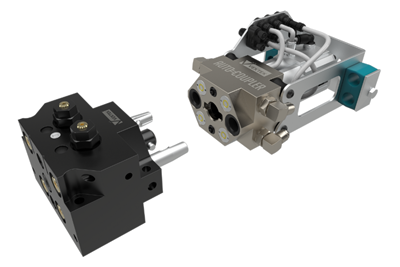

Read MoreVektek Automatic Coupling Device Provides Flexible Fixturing

Vektek’s Auto-Coupler features two independent air pass-thru circuits and provides the option of part present sensing and part confirmation.

Read MoreBoring Head Enables Sculpture Hardware to Be Machined on a Lathe

When small job shop Ansonia Manufacturing took on a tricky hardware component job for a “live” glass art sculpture, it realized a boring head would be needed to machine the part complete on its live-tool lathe.

Read More

.png;maxWidth=300;quality=90)