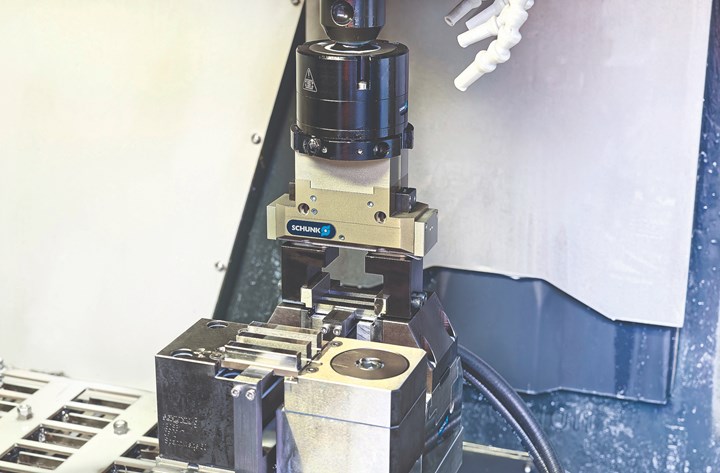

This “Lean Automation” solution uses machine tool elements such as spindle travel, toolholders, the supply of compressed air or coolant, the ATC and the workpiece — not a robot — to automate parts handling. Photo Credits: Deutsche Edelstahlwerke Specialty Steel

Every day, test engineers at Krefeld, Germany-based Deutsche Edelstahlwerke Specialty Steel (DEW) determine the quality of the steel it produces by way of tensile and notched-bar impact tests. With a length of 55 mm and a square cross section of 10 by 10 mm, the standardized test specimens are rather unspectacular from a machining perspective. Yet their production requires one operator to manually load about 2,500 individual samples each month.

“It takes around 15 minutes to produce a set of three specimens on our Doosan DNM 400 VMC once the job is set up,” explains Christian Richter, team coordinator material testing at DEW. “Two machining operations (op. 10 and op. 20) in two setups are necessary to machine each part. Although it takes little more than one minute to manually re-clamp the parts from op. 10 work to op. 20, the operator has little time to tend more than just the one machine.”

As a result, Richter investigated various possible automation solutions to increase flexibility and machine utilization. The goal was not to reduce staff but to open availability for employees to perform other more value-adding tasks. What’s interesting is that the solution the company chose didn’t involve a robot.

Letting the Machine Load Itself

After initial thoughts about having a robot tend the machine, the shop consulted with representatives from workholding equipment manufacturer Schunk, who suggested its “Lean Automation” solution. This solution is designed to easily, quickly and cost-effectively automate machine tools without a robot. The underlying principle is simple: Instead of investing in peripherals, elements already present in the machine are used to automate parts handling. These include spindle travels, toolholders, the supply of compressed air or coolant, the automatic tool changer (ATC) and the workpiece.

For loading, a Schunk universal gripper (that is clamped in the machine spindle using a conventional toolholder) moves to the workpiece magazine and removes a waterjet-cut blank to place it in a clamping block.

The necessary additional handling and cleaning modules are clamped into toolholders via a shank interface and placed in ATC pockets to be called up when necessary. Schunk’s Lean Automation grippers are actuated either with coolant or compressed air, which is supplied internally via the shaft interface with the connection module.

“We liked the idea of loading the machine from the inside as it was not only an economical way to automate it but safe and space-saving as well,” Richter says. “Everything happens inside the machine; shut the door and run,”

How it Works

For loading of op. 10 work, a Schunk universal gripper with GSW-B interface (which is clamped in the machine spindle using a conventional toolholder) moves to the workpiece magazine and removes a waterjet-cut blank to place it in a Schunk Tandem KSP-LH plus 160-IN pneumatically actuated, two-jaw clamping block. (The clamping block has an 8 mm jaw stroke and 20 kN of clamping force.) Then, the ATC swaps the gripper unit with a cutter for machining to begin.

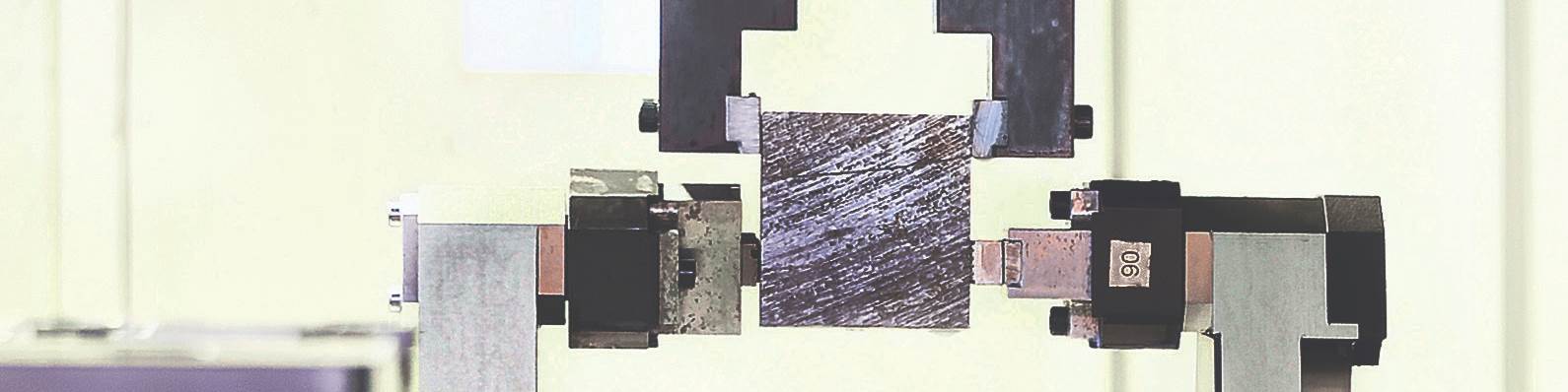

Once completed, the VMC swaps in the gripper that moves the machined parts to a station that rotates the workpieces 180 degrees. For the op. 20 work, the gripper places the indexed parts in the second two-jaw clamping block, a Tandem plus 160 with 3 mm of jaw stroke and 45 kN of clamping force. Finally, it loads a new blank into the op. 10 clamping block and the cycle continues. The clamping blocks are equipped with inductive monitoring of the jaw position to help ensure automation safety.

Both the op. 10 and op. 20 work consists of two succeeding machining operations to cut the blank into three specimens. Finally, at the end of op. 20, the three specimens are separated, pushed together as a package, removed with the gripper and placed in defined positions in the workpiece magazine.

“We do not need any special automation knowledge.”

To prevent excessive forces acting on the machine’s spindle during part loading, the spindle gripper uses a Schunk SW-B shank interface and compensation unit to adapt to inaccurate workpiece tolerances and positioning in six degrees of freedom. Before each machining cycle, the clamping devices, part indexing station and blank are cleared of chips and dirt using a cleaning device.

Increased Productivity and Flexibility

“Automating our machine with the clamping system, the indexing device as well as the ATC and workpiece magazines, we can maximize the efficiency and available space of the machine table,” Richter explains. “Whereas, in the past, each test specimen was manufactured individually, three specimens can now be simultaneously machined, and nonproductive handling and setup times reduced.”

In order to remain as flexible as possible and produce one-off parts despite the integrated automation solution, Richter equipped the machine with a Schunk Vero-S NSL plus 200 clamping station. The modular, quick-change pallet system enables precise resetting of workpieces, clamping devices or other equipment outside the machine.

After the last machining operation, the three specimens are separated, pushed together as a package, removed with the gripper and placed in defined positions in the workpiece magazine.

For Richter and his team, the greatest benefit of this Lean Automation solution is the operator’s increased flexibility and the value-add in having the person perform other tasks while machining of the test specimen runs unattended. They also appreciate that the system does not require any special robotics know-how. “Our operators’ programming skills are all that are needed to run the machine; we do not need any special automation knowledge, and can manage the process on our own and react flexibly if necessary,” Richter says.

Moreover, the Lean Automation system can be moved from one machine tool to another. Ultimately, it's about a gripper, a clamping system and a toolholder.

And the company’s next step is already in focus: “As soon as the employees are completely familiar with the new system and everything is working smoothly, we will implement the next stage of automation and produce several specimen sets unmanned,” Richter says.

Related Content

Tool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreWhat Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreRead Next

Video: Machine Shop Creates Robot Machining Cell Before There was Work for It

This machine shop’s self-integrated robot was purchased without a project in mind. However, when a particular part order came in, the robot paired with the proper machine tool was an optimal fit for the job, offering consistency and an increase in throughput.

Read MoreA Hands-On Approach to Cobot Gripping

As humans and robots begin to work closer together, grippers that have the flexibility of the human hand will be more in demand.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.png;maxWidth=300;quality=90)