Accuracy Helps Swiss Watches Keep Perfect Time

Production engineering solutions required by many Swiss watchmakers are already installed in their CNC machines when they buy them.

Production engineering solutions required by many Swiss watchmakers are already installed in their CNC machines when they buy them.

Bumotec, based in the tiny Swiss village of Sâles just a few miles from the Prealp mountains, pride themselves on not simply producing standard machines, but offering a complete production process as well. Customer parts have been tested on almost every machine the company sells, and machines come complete with the Alphacam CNC programs for those parts.

All Bumotec machines (supported by Starrag in the U.S.), which consist of turn/mill and multi-spindle, are adapted to provide specific solutions addressing the individual needs of each customer, ranging from three axes to 38 axes, using Fanuc controllers for machines with as many as 25 axes and Num brand controllers for those higher than 25.

About half the time in the factory is spent making the machines; the other half on programming and testing to ensure each machine leaves the factory with the optimized CNC code installed for accurately producing the individual customer’s range of complex components in the shortest cycle time.

Application engineer Pierre-André Brulhart says they devote about 2 weeks to programming each machine with Alphacam code and then run tests so it is ready to start production as soon as it is installed at the watchmaker’s facility.

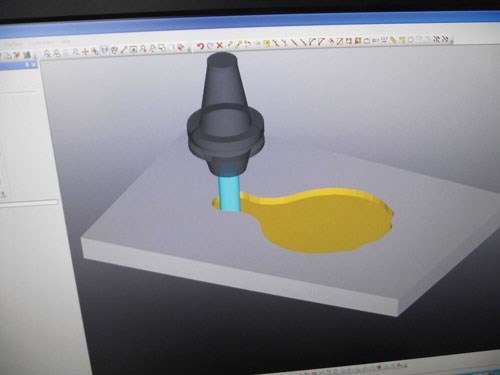

With a Swiss watch containing as many as 300 tiny moving parts between 0.15 mm and 50 mm, Bumotec’s turn-mill machines used to cut them have to reach a precision of about 4 microns and must constantly repeat that accuracy. Mr. Brulhart says Alphacam (part of the Vero Software portfolio) is perfect for the type of micro-machining required by many watchmakers.

“The tool paths can be created in a matter of moments, and its numerous features and functions ensure watchmakers can easily produce the complex components they need,” he says. He adds that Alphacam spends equal amounts of time on 38 axes as it does programming five-axis simultaneous milling.

A number of customized macros for the watchmaking industry have been developed by Alphacam’s Swiss reseller, MW Programmation. They include machining perlage (aspects of decoration such as circles, spirals and linear patterns); sequential numbering to automatically generate serial numbers of pieces without needing to change the NC program manually; palpage, which defines exact placement of the piece before machining; and diamond settings, allowing parameters of the amount, size and space between stones to be input.

MW Programmation works closely with Bumotec on every aspect of its customers’ needs, including the macros, post processors, training and a technical support hotline. While Bumotec provides its customers with initial training on Alphacam if they need it, MW has two training rooms at its headquarters in Malleray, in northern Switzerland, where the company can tailor both basic and advanced courses to individual customers’ requirements.

Director Marcel Weber gives an example of when the company worked directly with a Bumotec customer to address its need for machining parts by following the profile with a specific tool to create a chamfer. “As the main spindle doesn’t have a rotation frequency, it had to be angular controlled, so we developed a macro to control this all the way along the part.”

Not only are almost all Bumotec machines customized for their individual customers, but each post processor developed by MW for Bumotec is specific to the machine.

“As we use Alphacam to set the machines for creating the tool paths for our customers’ parts, we have four fully trained users, and three other staff are now starting to work with it,” Mr. Brulhart says. “Before a machine goes to the customer, we work on finding the optimum way for it to produce parts, and all the CNC programs are installed on it. The post processor is developed to be a unique driver specific to the CNC controller it’s working with.”

Bumotec Sales Manager Guy Ballif agrees with Mr. Brulhart that post processors are especially important to prevent crashes. “The cost of repairs to such hi-tech machines would be extremely expensive. All our post processors are produced and checked by MW Programmation, and we always feel very confident about pressing the ‘start’ button, knowing the post processor will accurately translate the instructions from Alphacam into the specific requirements of our machines.”

MW Programmation won the Alphacam Outstanding Achievement Award at Vero’s 2012 Global Resellers Conference for its specialist vertical market dominance, its 350 supported customers and for consistently gaining the highest revenue in the reseller channel.

A recent addition to Alphacam’s functionality is a Waveform 3D Roughing Strategy, which Mr. Weber says will be of particular benefit to the watch industry. “The new high speed machining technique maintains a constant tool cutting load by ensuring consistent tool engagement into the material. The tool moves in a smooth path to avoid sharp changes in direction, maintaining its velocity, dramatically decreasing the machining cycle time.”

This strategy, which is already proving popular with a number of MW’s 1,000 clients across Switzerland, is superior to the traditional roughing cycle where machinable geometry features are offset—inward or outward—by a stepover. Traditional tool paths have to run slower feeds and speeds because of the variable width-of-cut conditions encountered in corners. Tool load spikes as chip thickness increases in areas where the tool finds more material than it did while cutting in a straight line.

On the strength of its reputation in the watch industry, Bumotec has diversified into producing machines for other sectors requiring micro-machining, including medical, aerospace and jewelry. The company has plans to expand with a new modern factory nearby.

Mr. Ballif predicts a strong future for Swiss watches, thanks to their long-standing tradition. He says there will always be a market for fine, well-made watches that are accurate to within a second per month. And with such watches being fully mechanical and not electronic, there will always be a need for accurate, micro-machining of the tiny complex parts, programmed with Alphacam.

— EDGECAM | Hexagon Manufacturing Intelligence

Related Content

Lone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

Read MorePrecision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

Read MoreThe Value of CAD/CAM and Cutting Tool Manufacturers Working Together

Overall machining efficiency can be increased when software and tooling companies combine to tackle machining challenges.

Read MoreIntegrated CAD/CAM Software for Maximum Efficiency

PMTS 2023: This software solution is said to enable users to take advanced mill-turn and Swiss-type machining to new levels of speed, efficiency and simplified programming.

Read MoreRead Next

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)