Cost Efficiency with Hard Part Turning

Either as an alternative or complement to grinding, hard part turning offers a number of advantages that have become even more evident with further developments in insert concepts.

Machining components in their hardened condition, either through-hardened or case-hardened, has many advantages in helping to achieve better accuracy more efficiently. As it has gained interest and become more common, hard part turning has driven several recent tooling developments. An obstacle that was overcome some years ago was that of suitable machine tools, and although some lathes are more suited than others for the stability-demanding setups necessary for this area, most modern CNC lathes are capable.

Hard part turning has its own set of demands in that cutting forces and pressure on the tool are more severe than they would be with materials in their green condition. Also, the hard workpiece material is abrasive, so more wear and heat are generated. There are, however, tool materials well-suited to this area—primarily cubic boron nitride (CBN), which is second in hardness only to diamond. Today, a range of excellent insert grades, with CBN particles as the main constituents, is available for hard part turning.

Insert Efficiency Here

Because feed rate ultimately determines the amount of time a job will take, improving feed rate can result in considerable savings of production hours and costs. New developments in cutting tools are improving efficiencies—sometimes as dramatically as tripling the feed rate. “Feed rate is where we will really improve things,” explains Martin Saunders, an application specialist in turning. He cites two examples of manufacturers who made overnight productivity improvements of 116 percent and 322 percent, respectively, simply by switching to a different insert for their turning projects in CNC lathes. No new machinery or methods were required.

“What is very positive about the insert these companies use,” Mr. Saunders says, “is the higher feed rate still achieves very good surface finishes. A feed of 0.3 mm/rev (0.12 ipr) generates a surface finish of less than Rz 1 micron (Ra 0.14 microinch). Even a feed of 0.5 mm/rev (0.20 ipr) will give less than Rz 5 microns (Ra 0.7 microinch). To put this into context, when common surface finishes for turned parts are Rz 6.3 microns (Ra 0.88 microinch), feeds of 60 to 65 percent slower would be required if a standard insert with a radius-based nose-corner was used.”

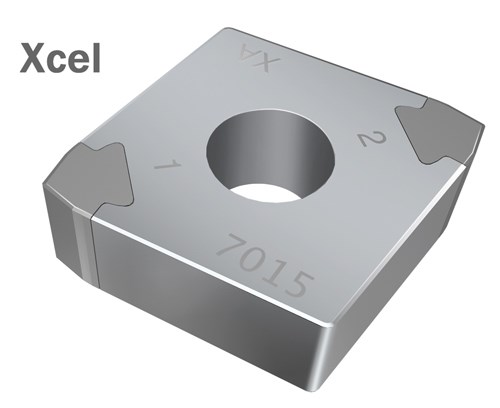

The insert that is providing productivity improvements on this scale, bringing a generational boost to hard part turning performance, is the Xcel-type insert from Sandvik Coromant. Sacha Kotarac, an application specialist with experience in problem solving for engineering companies, lets the surface finish determine his application of the insert. “I introduce Xcel as much as possible for finish-turning as long as the surface finish demands are achievable,” he says. “And I also use the feed-rate capability as much as possible for roughing operations. As long as I have sufficient clearance against any shoulder, the inserts can be applied with feeds up to 0.5 mm/rev (0.02 ipr), when normal stability is there. We are talking about rates twice that of wiper inserts. The Xcel and wiper inserts should also be seen to complement each other, often providing a stable operation with predictable results.

“One manufacturing company we worked with was planning to replace its grinding machines with lathes for hard part turning. In this case, we saw the best solution was to use Xcel for roughing, followed by Sandvik Coromant’s WG-type wiper designed for semi-finishing operations. We ran a trial on their machines and presented them with the results and machining times,” Mr. Kotarac adds. “The outcome was that the customer thought it worthwhile to change all of the component drawings to introduce sufficient clearance to take advantage of the Xcel capability and tasked us with fully equipping the machine. We recommended a feed rate of 0.4 mm/rev (0.16 ipr) for roughing with Xcel, generating a surface finish of Ra 0.5 micron (20 microinches). For the WG insert, the feed rate is 0.33 mm/rev (0.12 ipr) generating a finish of Ra 0.42 micron (17 microinches).”

For Best Results

Stability is a success factor for all CBN-insert applications, but the Xcel insert emphasizes it. To make sure conditions are optimum for success with this insert, the length-to-diameter ratio should be kept to less than 4 to 1. This is not to say it will not work at a higher ratio, but 4 to 1 or less provides the absolute best conditions.

The standard round-nose insert generates the lowest cutting forces, but the feed rate is strictly limited to the relationship between the nose-radius and the surface finish. Sandvik Coromant’s wiper insert with WH geometry gives a high surface finish at a higher feed, with a relatively low stability requirement. Next, the wiper insert with the WG geometry gives an even better surface finish at an even higher feed, but it needs more stability. When the Xcel insert can be used, it gives high surface finish at high feeds, but with low stability requirements. Even at low feed rates, this insert will generate very good surface finishes. The feed rate relationship with surface finish is always the key parameter when the focus is on minimizing cutting times.

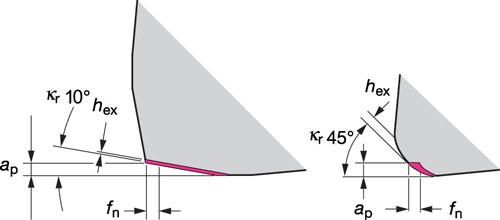

With a small entry angle of 10 degrees, the depth of cut is limited—but it would be limited in hard part turning anyway. With conventional round-nose inserts, the chip thickness varies along the edge. With the Xcel, however, there is a uniform, thin chip, allowing for the high feed rates. A main part of the innovation is the way the straight part of the edge blends in with the specially developed wiper, which forms the transition to the back clearance part of the edge.

While the depth of cut capability of the Xcel insert is limited by the straight edge, normal depth requirements in hard part turning are usually about 0.20 mm (0.008 inch). The capability of the insert is best used when one-pass operations can be applied, using the entire cutting edge with depth-of-cut capacity and the highest feed that the surface finish limit will allow. For semi-roughing operations, the stability is sometimes the limiting factor.

The insert can improve tool life as well, spreading wear evenly across the edge. A standard round-nose insert experiences more extensive wear at the depth of cut on the cutting edge, limiting durability. The improvement is partly because of reduced temperature generated through the shorter contact time in cut, spread out along the longer straight edge. Consequently, more parts can be machined with Xcel, even at the highly elevated feeds.

Making the Grade

Xcel inserts come in two grades based on cubic boron nitride (CBN). This is a tool material of high hot hardness designed to resist plastic deformation, making it capable of high combinations of feed and cutting speed in hardened materials. Today’s grades also have good toughness for strength and good resistance to withstand thermal shocks. Grades today have a CBN-content of 40 to 65 percent, with a ceramic binder to add the chemical wear resistance needed at high temperatures. These grades are mechanically strong so as to be resistant to abrasive wear. Additionally, there are even higher content CBN grades with metallic binders for more toughness.

Continuous or interrupted cuts make different demands on the cutting tools. To optimize hard part turning operations, it is important to apply the most suitable grade. For continuous-finish turning, especially case-hardened parts needing optimal wear resistance, CB7015 provides a very good combination of high metal removal rates and durability. This performance is based on a fine-grain size in a specially developed ceramic binder, which allows the grade to develop wear slowly, in a controlled manner, along the edge of the Xcel insert. Continuous cuts with or without light intermittence are ideal for this grade.

When intermittent cuts prevail and are heavier, a tougher grade such as CB7025 is the best choice. This grade has the capability to generate high surface finishes when there are interruptions in the surface, such as on gear wheels or slots in shafts or when some instability is present in the setup. It is also a modern fine-grain CBN grade in a ceramic binder developed to have the strength to cope with these types of demands.

Related Content

What Is Trochoidal Turning? How Might Shops Benefit From It?

While trochoidal milling might be a more well-known toolpath strategy, trochoidal turning can offer similar benefits such as high material removal rates especially for rough-turning operations.

Read MoreReplaceable-Insert Spade Drill Basics, Advantages

Although solid carbide and indexable-insert drills have their place in a machine shop, replaceable-insert spade drills offer specific advantages for various holemaking operations on machining centers and lathes.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreRead Next

Getting the Most Out of Hard Turning

Traditionally, production of most parts made from hard or hardened materials, defined as those at or more than 45 HRc, required dedicated grinding equipment and processes.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More

.png;maxWidth=300;quality=90)