Hard turning is typically defined as the turning of a part or barstock of harder than 45HRC on a lathe or turning center. Since surface roughness of Rmax/Rz=1.6s can be achieved, hard turning is often considered a replacement for grinding operations or as a pre-grinding process. Hard turning is most often performed on post-heat treated parts with surface hardness ranging from 45HRC to 68HRC or even higher.

The process of hard turning shares many fundamentals with its “soft turning” sibling. As with any new application, there is a learning curve for hard turning, but the fundamental principles follow those of the same turning operations that are commonly performed in shops today. This gives it an inherent advantage over grinding, which requires specific knowledge and experience that not all machinists possess. While any new process can be learned, most machinists and programmers today will have an easier time absorbing the hard turning process compared with grinding.

The Right Application

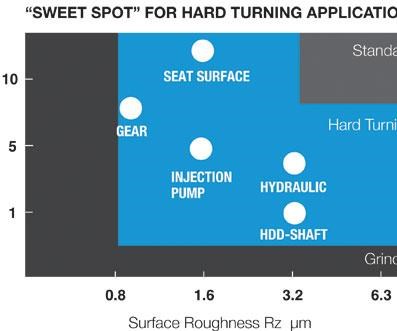

While hard turning can achieve impressive results, it is not an alternative for all parts typically finished through grinding. Polished mirror surface finishes of Rz=0.3~0.8z that can be achieved through grinding are not possible by hard turning alone. Grinding has the additional advantage of being able to achieve higher dimensional roundness and cylindricity accuracies compared with hard turning. However, since parts can typically be finished in a single chucking, hard turned parts often show superior concentricity and perpendicularity characteristics to their ground counterparts.

The “sweet spot” for hard turning applications are for parts that have roundness accuracy requirements between 0.5 and 12 microns, and surface roughness requirements between Rz 0.8 micron and Rz 7.0 microns (see chart on page 26). This includes a variety of parts such as gears, injection pump components, hydraulic components, seat surfaces, and hard disk drive shafts.

The cost advantages of hard turning compared with grinding are numerous. The immediately apparent cost advantage is the reduced cost in capital equipment, as CNC turning centers are generally less expensive than grinding machines. Additionally, several types of grinding machines may be needed to perform the operations able to be performed on a single turning center, further opening the possibilities for equipment cost savings.

As mentioned above, a turning center can complete ID turning, OD turning, taper turning, and grooving in a single chucking. In addition to improving the accuracy of squareness, concentricity and straightness, this drastically reduces cycle and setup times as well. High precision threading operations can also be performed, guaranteeing concentricity with other part features compared with offline threading operations.

Hard turning also allows for the finishing of radius and free-curved surfaces. Grinding processes require a custom-dressed wheel, which is time consuming to produce, or highly customized grinding machines that can be expensive.

In addition to the inherent cost advantages of combining multiple operations into one, hard turning cycle times are drastically shorter than comparable turning operations. Metal can be removed much faster in hard turning operations, and high speed turning is possible with both CBN and ceramic cutting tools. Changing grinding wheels is also time consuming, whereas switching out inserts on turning centers can be quick. Part loading and unloading times are also shorter for turning centers, and turning centers are typically more easily automated for additional productivity.

A number of features of the hard turning process reduce environmental impact as well as cost. Turning centers consume less electricity than grinding machines, reducing both electrical consumption and the monthly electrical bill. Hard turning is often performed dry, eliminating both coolant costs and the need for coolant disposal. Hard turning produces easily recycled chips, whereas grinding produces sludge that must go through a costly separation process or be disposed of as industrial waste.

The Right Machine

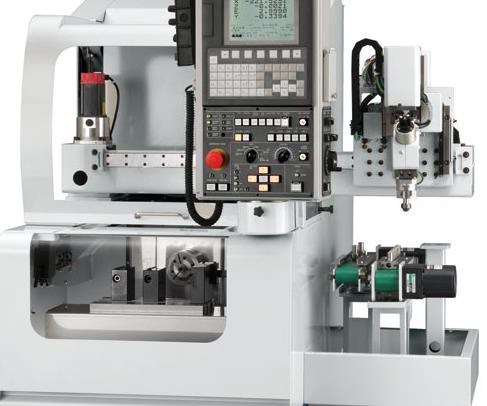

As accuracy and surface finish are fundamental requirements for hard turned parts, not all lathes and turning centers are ideally suited for hard turning applications. In addition to being able to meet the speed requirements of the cutting tools, machines used for hard turning must maintain thermal stability, rigidity and precision over time.

Avoiding heat buildup is critical for precision machining. Special care needs to be taken to make sure that the heat generated is not only transferred away from the cutting edge, but that it also does not reside within the machine and compromise accuracy. To resolve this issue, Miyano has designed its GN-3200 hard turning machine with a symmetric machine frame and bed. The wing-style headstock features a design that allows for spindle growth without degradation in part quality and accuracy. The built-in spindle also contains an automatic cooling system to maintain constant temperature. Finally, should coolant be used, the coolant tank is separated from the machine, keeping hot coolant away from the casting and preventing this heat from being transmitted to the machine body.

Heat is not the only nemesis for high precision parts; suppressing vibration is also essential for hard turned parts. A rigid machine casting is the start. Additionally, dovetail slideways provide higher rigidity than linear guide construction, and the company uses dovetail slideways on all GN Series machines. They are hand scraped not only for precision, but also for damping performance. As an added precaution against vibration, the built-in spindle and the built-in sensor are beltless in order to achieve smooth rotation with minimum vibration. Short overhang and rigid tool setups are also required to minimize vibration.

High precision positioning is an additional machine requirement for hard turning applications. On the GN-3200, the tools on the X axis and spindle on the Z axis slide independently, eliminating the compound tolerance issues traditionally associated with turning centers. The single slide structure of turret traversing on the X axis and the spindle traversing on the Z axis achieves almost zero lost motion by improving follow-up accuracy. The GN series machines also precisely control the discharge of slideway lubricant, ensuring the machines’ ability to perform heavy duty, high precision turning. Additionally, the controls feature an input tolerance of only 0.1 micron (4 millionths). These features, plus very high precision spindle bearings, help the machine to maintain positioning accuracy and produce better finishes for the skim cut after the primary cut on tight tolerance parts.

The Right Tooling

One of the key benefits of hard turning is that off the shelf inserts can be used for virtually any hard turning operation. However, the CBN, PCBN and ceramic inserts can be expensive, especially when compared with the relatively low costs of grinding wheels. But don’t let the high cost of inserts scare you off from the hard turning process, as the high tooling costs are quickly offset by reductions in processing time and change-over time.

CBN and PCBN are ideal cutting tool materials for the hard finishing of parts above 55HRC. CBN is one of the hardest materials, second only to diamond. It is a manufactured material, synthesized under conditions similar to those used for synthetic diamond. However, unlike diamond cutting tools, CBN demonstrates increased stability at higher temperatures. CBN is also used to manufacture PCBN, a composite formed by sintering CBN particles into a hard, tough and thermally stable material.

Thanks to their incredible wear resistance, CBN and PCBN cutting tools outlast carbide by a large factor in hard turning applications. However, they are extremely brittle, and therefore, not well suited for anything other than finishing operations with smaller depths of cut.

Ceramic cutting tools are considerably less expensive than CBN and PCBN, and also provide an excellent surface finish thanks to their ability to maintain a sharp cutting edge. They typically offer enhanced toughness over CBN and PCBN, making them better suited for hard turning materials in the 45-55 HRC range. However, similar to CBN and PCBN, they are brittle and not well suited for interrupted cuts, roughing or semi-finishing.

Geometries and coatings on CBN, PCBN and ceramic inserts can be selected for optimal performance in individual applications. No matter what cutting tool is chosen, an accurate and rigid toolholder is also essential to the process. Maintain a minimal projection length to minimize vibration, enhance part finish and maximize cutting tool life.

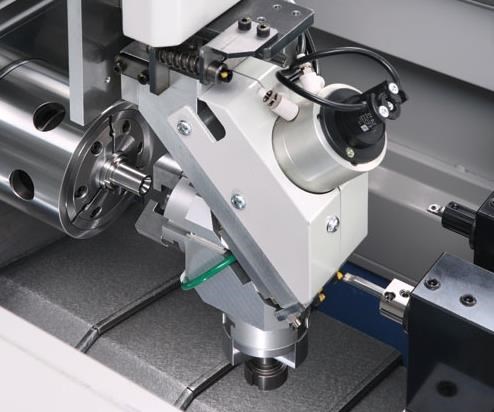

Even though these cutting tools can provide surface finishes of Rmax/Rz=1.6s, feed turning marks (similar to the peaks and valleys of threading) remain on the surface. This may be an issue for parts such as oil seal contact surfaces, where the valleys may cause oil to leak, or bearing rolling surfaces where the peaks may cause the bearing material to detach. For better surface finish on a turning center, a film-type grinding unit can be used to achieve surface finishes of less than Rz0.8 micron. Film-type grinding units are for turning centers with driven turrets, and attach to the tooling turret as a driven tool would. They use a variety of polishing films to grind off the peaks left by hard turning, providing surface finishes similar to traditional grinding methods.

Benefits of Hard Turning

Although hard turning it is not an alternative for all grinding operations, the potential cost savings from reduced setup times, faster cycle times and lower equipment costs are too big to ignore. Since it shares many fundamentals with standard turning processes, hard turning has the additional benefit of being able to be easily assimilated into most shops. With a little help choosing the right application, right machine and right tooling, hard turning can quickly enhance the profitability of a variety of tight tolerance applications.

.jpg;maxWidth=300;quality=90)