Inspection System Helps Company Meet Short Lead Times

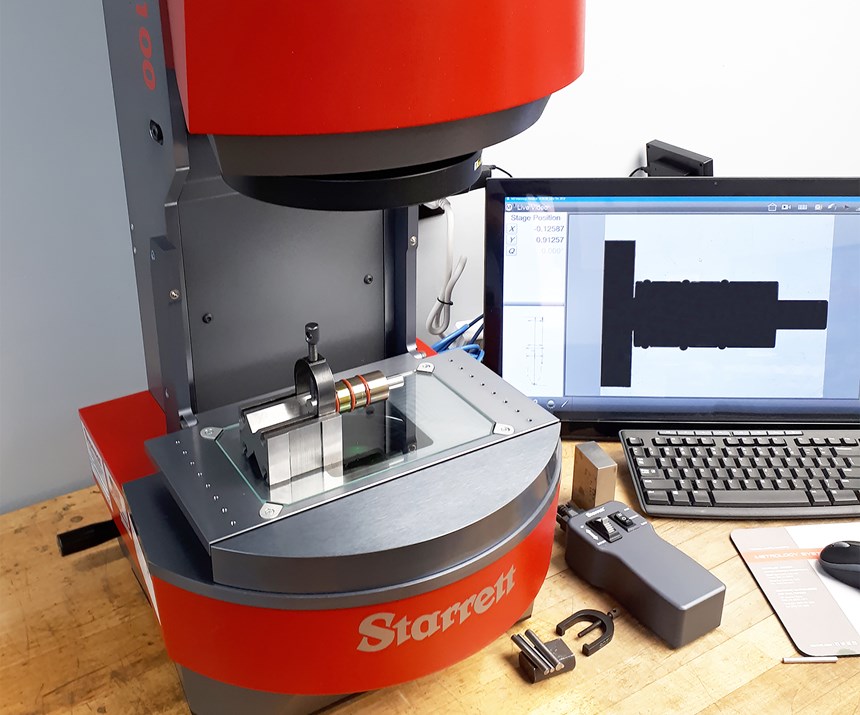

A digital video inspection system from Starrett is increasing this company’s inspection throughput and helping it get parts to its customer on time.

Oftentimes, reducing machining time alone is not enough to meet challenging lead times. Shops may need to look at other processes to ensure the parts get to the customer on time. B.C. Instruments, a Schomberg, Ontario-based company, purchased new machines to keep up with a customer’s expedited lead times. But it quickly realized that even with the ability to produce complete parts in less than two minutes, it would not meet lead times if it had to spend three or four minutes inspecting each part. A new inspection system from The L.S. Starrett Co. (Athol, Massachusetts) has increased inspection throughput by 75 percent to help the company hit its customers’ lead times and perform additional inspection tasks.

Bruno Conzelmann established B.C. Instruments (BCI) in his garage in 1971. Since then, the company has grown to include 150 employees working in six plants across Ontario and a plant in India. Despite this growth, BCI is still family owned, with Mr. Conzelmann’s son Roger currently serving as the company’s president. “We’re a fast-growing company that takes pride in retaining and taking care of our employees, without a single layoff,” says Sean Smith, plant manager of small-diameter turning.

BCI produces precision parts for a range of industries, including aerospace, medical, power generation, nuclear and electronics. The company also produces parts for the injection molding industry, including families of injection molding nozzles. These nozzles can have different thread sizes, OD profiles and internal features. They also have tight tolerances, within ±10 microns, Mr. Smith says. He also notes that BCI is the sole supplier of nozzle tips for a customer, which has very short lead times. “Demand is high, and our customer is trying to grow by 20 or 30 percent,” he says. The expedited work, combined with a stocking agreement BCI must maintain, put the company in a challenging situation. To keep up with the work, it purchased two new Citizen lathes, which can manufacture complete parts in two minutes.

Mr. Smith and quality insurance inspector Brent Cordy knew that the facility was going to need a more efficient inspection system to keep up with the parts coming off the new machines. The company performs 100 percent inspection on these parts, and Mr. Cordy estimates that inspectors spent 3 to 5 minutes measuring each part on the company’s profile projectors. Facing a bottleneck in inspection, the two launched a continuous improvement project to find a faster system.

This led them to the Starrett booth at the 2017 CMTS trade show, where they saw the HRV100-FLIP digital video inspection system. They were so impressed that the day after they visited the trade show, they purchased the unit that had been on display. “I didn’t let it go back over the border,” Mr. Smith jokes.

Increasing Throughput

Mr. Smith and Mr. Cordy say the Flip system has several features that have enabled BCI to increase its inspection throughput:

Fast program creation. According to Mr. Cordy, he and the other BCI inspectors were able to quickly learn the new system. Users can create inspection programs for new parts by tracing them on the system’s touch screen and choosing the correct measurements, angles, distances and line straightness. “It’s pretty intuitive,” he says. Employees were able to create their own programs in less than a week, and they can now create two or three programs per day.

Automatic part recognition. Once the program is created, Mr. Cordy says it only takes a few seconds for the system to inspect a part. It has automatic part recognition, which establishes and recognizes the OD feature of the part, pulls up the correct program and inspects the part automatically.

Multiple part inspection. The system also has the capability to inspect multiple parts at the same time. Mr. Smith says BCI can fit as many as 10 injection molding nozzles on the FLIP system at once.

System Flexibility

BCI also benefits from the system’s flexibility:

Configuration. The Starrett FLIP can be configured horizontally or vertically, and the company has its system on a table that enables users to switch the orientation based on part size and fixturing. “Depending on the application and what we’re checking, sometimes it’s easier to do it vertically or horizontally,” Mr. Smith says.

Custom thread measurement. The system can also measure threads, which BCI finds especially helpful, as the nozzles have external threads that must be checked. The software can also be configured to measure custom thread sizes, which the company uses for parts that are plated after machining.

Location. The HVR100-FLIP system is suited for industrial environments and can be used on the shop floor. BCI has its system located at the front of its shop floor so a range of employees can access it for different types of inspection. Inspectors can check finished parts, and machinists can also use it to cross-check parts for tool wear and to help calculate offsets.

Benefits

Overall, Mr. Smith and Mr. Cordy say the FLIP system has exceeded their expectations. They estimate that it has increased inspection throughput by 75 percent. The system is so efficient that the shop is finding other uses for it beyond the nozzles, such as incoming inspections. “We measure a lot of our subcontractors’ work,” Mr. Smith says. “This system has allowed us to get through this type of sample inspection check.”

The system is also freeing up employees to take on other work. BCI has 30 “tech support” employees who are qualified in, but not dedicated to, inspection. Since implementing the Starrett FLIP system, the company does not need to task these employees with inspections as frequently. Instead, they can work on setting up machines or other continuous improvement projects. BCI, like many other shops, is continually seeking skilled workers, so using its employees as efficiently as possible is important.

This company recently purchased a second FLIP unit. When it arrives, the company plans to temporarily place it in a neighboring building to help overcome an inspection backlog, and then eventually move it to another plant.

Related Content

How Well do You Know Granite Surface Plates?

Here are some tips for choosing, maintaining and customizing a granite solution that will best meet your shop’s particular inspection needs.

Read MoreStreamlining Part Measurement, Data Collection Processes

When collecting measurement data automatically with a wireless data collection system, manual errors can be eliminated ensuring data accuracy and traceability.

Read MoreKeeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreShop Finds Value in Simple CMM Programming

Icon-driven programming enables all shopfloor personnel to perform CMM inspection, not just those in the quality department.

Read MoreRead Next

Emerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More