Profiting with Shop Management Software

Once all employees can see how process changes can benefit them, implementation becomes easier and efficiency soars.

Companies can employ various strategies to make their processes run more smoothly. Eventually, certain solutions tend to prove themselves as most effective and move to the forefront as employees buy into the advantages they present. It can be the same in any business. If an idea makes the job easier, makes the employees more productive, and makes the company more profitable, everybody wins.

Every once in a while, an idea or process proves so effective that it becomes a key component in the core functionality of the business. For one Chicago-area shop, implementation of shop management software stretched far beyond machine scheduling, its functionality streamlining operations by allowing clear measurement of employee performance.

Two Types of Metalworking

Smith & Richardson Inc. (Geneva, Ill.) opened its doors in 1921 as a chaplet manufacturer. Chaplets are metal spacers used in sand casting operations to keep cores from shifting. While these stamped parts have remained a staple of the company’s business throughout the years, machining operations have also made their mark.

In 1985, the company acquired a Brown & Sharpe screw machine business. At one time it housed 32 Brown & Sharpes on the floor, but has since converted essentially all of its machining operations to CNC. One Brown & Sharpe remains in its original form while the other four still on the floor have been converted to CNC. Four Citizen Swiss machines, three fixed headstock lathes (two Hardinge, one Eurotech) and a vertical machining center make up the balance of the chip cutters.

The chaplet business is all transportation-related, for automotive/heavy truck. “The machines used in the foundry side of our business are proprietary to Smith & Richardson,” says Carlos Balandrin, vice president of manufacturing. “The rate of speed at which they can produce and their accuracy give us quite a bit of a competitive advantage—high volume, quality chaplets at a very low cost.” Some of these machines have been on the floor since the ‘30s and ‘40s (rebuilt). Chaplet jobs can run on a machine for as long as a month, producing close to 200,000 pieces. A typical change-over might take 8 hours.

The machining business is more widespread in its delivery, reaching such industries as hydraulics, instrumentation, IT, plastic overmolders, medical, defense and commercial aircraft. Here, the company is more of a short- to medium-run producer of parts, with runs typically from 50 to 25,000 pieces. The majority of the parts have EAUs (expected annual usage) of less than 100,000, with some as low as 500—they do a lot of setup on this shop floor.

The materials gamut includes 12L14 and brass, stainless (including medical grade), titanium, Hastelloy, and even a minimal amount of plastics. The company has been seeing recent growth in the medical market, both from a device standpoint and for pneumatics, including a high number of medical grade cylinder components.

The company has 38 employees to cover two manned shifts. All of the CNC machines (as well as some of the presses) can also run untended during the third, unmanned shift. But some jobs, because of tight tolerances or the material being run, require an operator to be present. Each machine is equipped with a mist collection system and high pressure coolant

capabilities.

Managing the Big Picture

Smith & Richardson had been using an accounting program that had effectively served its intended purpose, but management saw a need for something beyond counting and inventory management. It needed shopfloor control.

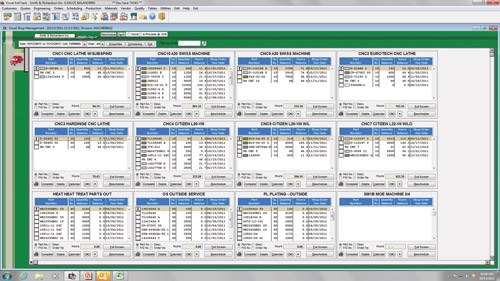

At the end of 2006, the company implemented new shop management software—Henning Software Inc.’s Visual EstiTrack and Visual Books ERP package. Through December of that year, the company ran a dual system between the old and new software, allowing a gradual transition. During that period, management worked hard to create group buy-in throughout the organization. The new software required some additional processes on the shop floor, but it was clear the extra steps would save time in the long run. “Employees have adjusted well,” says Renee Schroeder, vice president of operations. “We’ve seen dramatic changes in the organization with the ability to collect production data and monitor it.”

Seven touchscreen terminals and two computers are strategically placed throughout the shop floor. Each station is equipped with a scanner for gathering workorder data, a Zebra printer for move tickets and a separate keyboard for entering or editing data. The software resides on a central server where all of the data is stored. The entire system is networked to allow the data to be accessed from any computer within the company or through the internet with appropriate password authorization.

“We are using the software for full shopfloor control,” Mrs. Schroeder says. “We do all of our scheduling through it.” When starting a setup, the operator scans the workorder and the system initiates the job. After the setup, the operator scans the job ticket, and it populates the data on the screen. The clock starts ticking after “Start/Run” is pressed. At the end of a run or at the end of a shift, the operator views the job card and enters the numbers of pieces produced and scrapped. “It’s real-time data, so I can pull up a job card at any time and see when a job went into setup and how long it should take. We now have a much clearer picture of what’s going on at all times.”

The schedule is fully integrated into the system, and Mrs. Schroeder is now working on better methods of advanced planning to simplify scheduling and providing delivery dates to customers. Currently, a scheduler has total control of when a job will be run and communicates that information to customer service, who then can share the information with the customer. But she would like customer service to just as easily be able to look at machine availability and determine how quickly a job can be worked in. Although the scheduler will still be required for handling adjustments as issues arise, shortening the window of communication time adds to the efficiency of the entire process.

Forest Through the Trees

Businesses will almost always face hurdles and commonly face some resistance when making significant procedural changes. Adjusting to data collection on the shop floor at Smith & Richardson took longer than any other part of the software because it was an entirely new process for all of the employees. Mr. Balandrin says, “It took more than a year before everyone was accustomed to clocking in and out of their jobs. It’s sometimes hard to get people to change when they’re used to doing things a certain way, and we were prepared for that.”

But one of the biggest challenges took management by surprise. “One mistake we made,” says Rich Hoster, president and COO, “was assuming that everyone knew how to operate a computer. When we put all the data collection terminals throughout the facility, many people were intimidated. They didn’t know how to begin to use them.”

Today, data collection is an expected behavior, and it is not an issue. “Even with new employees, they come in and see the culture on the floor and naturally adjust to reporting in,” Mr. Balandrin says. “Yes, we make mistakes. Sometimes an operator may hit a wrong key and maybe report 500 parts instead of 50. But as they review their efficiencies, they’ll often catch this, and everyone has become very good about informing us if they realize they may have made a mistake.”

Staying on top of efficiencies has helped the company locate issues in the manufacturing process as well as refine expectations. “When we started collecting data, we made it clear that we weren’t going to hold everyone to the engineering master times immediately,” Mr. Hoster says. The software is intended to be a tool to improve the process, not create a stressful environment. “If we can’t meet the specified times, for any reason, we want people to speak up. Then engineering can look at the process and identify shortcomings. Sometimes we find that a process just isn’t capable of meeting the engineering master time, and we make an adjustment there.”

Encouraging this line of communication has led to operators identifying target numbers that are too low as well. “I’m consistently getting more pieces per hour; it really should be a higher rate,” Mr. Hoster says he’ll hear from employees. “It’s good to see that people are really encouraged,” he continues. “We’ve tried to drive the message home that we’re all in this together. Customers don’t care what the excuse is. They only care that we get them quality parts when we said we would. So if something is happening in a process that is affecting a customer, it is affecting everybody in some way.”

Using it Pays

Because of the software’s effectiveness, Smith & Richardson has found other ways to build the efficiency tracking functionality into the business plan. A couple of years ago, the management team organized a plan to work efficiency into the compensation plan as a variable pay system.

Depending on where an employee is in the organization, either 10 or 20 percent of his or her compensation is variable on a weekly basis. Five categories are considered to determine the compensation amount: on-time delivery, setup and operating efficiency, non-conformances, safety and discipline and attendance.

The salaries are affected as a group. Everyone gets a base pay, and the variable portion is calculated on top of that. Everyone either gets 100 percent or misses out on an equal percentage. This structure allows the group to encourage each other to be more diligent and aware of performing to the best of their abilities.

“Everyone’s efficiencies are posted on a daily basis, and people notice what’s going on around them,” Mr. Hoster explains. “If they start to see something that doesn’t make sense to them, they’ll question the behavior and try to encourage changes. Sometimes they’ll work among themselves to make situations better, or if necessary, they will come to managers with suggestions. Either way, we’re problem solving and finding better ways to run the business.”

Because it is collecting efficiencies, the Henning software has played a big part in the company’s ability to determine appropriate compensation. These capabilities have carried over to the bonus system as well. On top of any annual cost of living increases the company may give, it also awards employees quarterly bonuses based on merit. “We look at how each employee is performing from an operations standpoint, from a setup standpoint, attendance, and if they are bringing suggestions and making changes,” Mr. Hoster says. “When we sit down with an employee for a review, I like being able to present the perspective that actual numbers provide. The software allows us to be objective in our decisions.”

Real Results

Describing the big-picture benefits of the software, Mrs. Schroeder stresses that the company now has the ability to measure productivity. She explains that it has led to a dramatic improvement in on-time delivery. “That’s something we could measure, and our numbers were not where they needed to be,” she says. “Before, we could not get above 80 to 85 percent, but now we’re consistently above 95 percent.”

Mr. Hoster looks at the profitability of specific products and sees the way the software has allowed the company to focus on the work best suited to its capabilities. “From a costing standpoint, the software allows us to see how we performed on previous jobs,” he says. “Are we hitting the profit margin we’re shooting for? We’ve obsoleted some products based on the data we were getting. For others, we’ve gone to the customers and shown them that we hadn’t been profitable in the past, shown them our data and agreed to price increases.”

It’s easy to see why company management is excited about the results of its shop management software. But the buy-in from shopfloor personnel was essential to making it effective. Smith & Richardson has found the right balance to bring all of the pieces together.

Related Content

Datanomix Automated Production Intelligence Platform for ProShop ERP Software

PMTS 2023: Automated Job Costing analytics compare ProShop ERP target cycle times to actual process performance in the Datanomix Automated Production Intelligence Platform.

Read MoreERP Software Enables Manufacturers to Maximize Operational Efficiencies

PMTS 2023: JobBoss2 from ECI Software Solutions assists manufacturers with decision-making and reveals opportunities for growth and cost savings.

Read MorePrecision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

Read MoreAvoid the 7 Deadly Sins of Manufacturing

Identifying and preventing these manufacturing sins will reduce or eliminate unnecessary waste, improve efficiency and productivity as well as protect profitability and cash flow.

Read MoreRead Next

Cloud Computing in Manufacturing

Cloud computing has potential to be game-changing technology in manufacturing for everyone from small shops to extremely large manufacturing plants.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)