Strengthening Grip

Workholding for milling operations commonly involves vises that clamp with movable jaws. This technology has continued to progress to match the requirements of five-axis workholding.

Workholding for milling operations commonly involves vises that clamp with movable jaws. Just as this technology has developed to keep up with the advancement of machine tools, manufacturers have also designed vises specifically to match the requirements of five-axis workholding. But this machining process has presented some unique challenges.

Addressing a Need

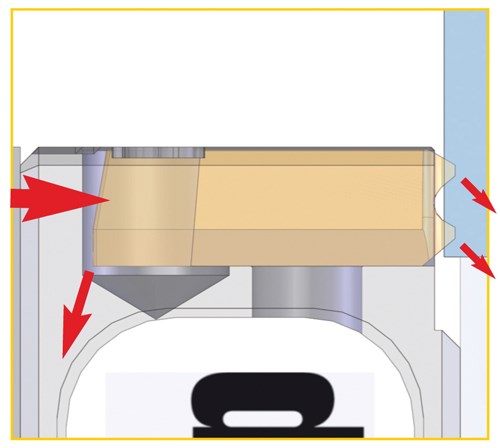

OML’s SinterGrip vise jaws put an unbreakable grip on only 3.5 mm of material to allow aggressive five-axis machining of high-value workpieces, with minimal waste material. With all but 3.5 mm of the workpiece held above the vise, these jaws give access for machining with short cutting tools for high-rate metal removal and high accuracy in a single setup. Designed for medical and aerospace parts, this jaw concept received first prize for technical innovation in tools and equipment at Europe’s 2013 Industrie Lyon trade fair. The design eliminates the need for a special vise, special tools, or pre-machining of the workpiece to add a gripping feature, such as a dovetail.

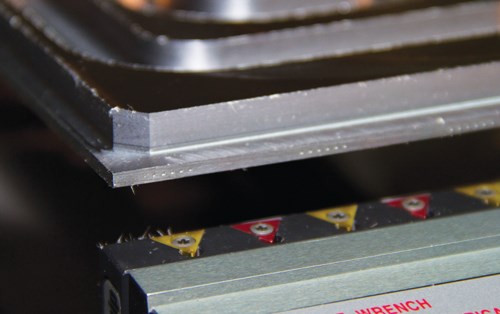

Developed primarily for use with OML’s MC and Genius vises, SinterGrip jaws use scientifically designed, serrated, carbide inserts to penetrate the workpiece edge to a minimal, controlled depth and exert a push-down force on the part. Thin parts can be machined without deformation by clamping them at 6,600 pounds of force to achieve penetration, then lowering the force to 2,200 pounds with no loss of gripping power. The jaws can also grip equally well on as little as 2 mm of part surface if required by the application.

The jaws are available in widths up to 8 inches (200 mm) and can be installed on most vises with mechanical, mechanical/hydraulic or hydraulic clamping systems. A starter set includes the tungsten-carbide-coated jaws, retention screws for the inserts, and a pair of OML’s snap-in CLAK parallels for quickly positioning a workpiece at the ideal gripping height. The carbide coating on the jaws enhances grip for secondary operations. Jaw sets are also available without the carbide coating and in styles for the user to machine to size. The serrated inserts are sold separately, with three types available for standard steels, hard materials and aluminum.

The Science

The SinterGrip jaws and toothed, carbide inserts are engineered to work together to secure the part and create two types of push-down effects on it. Each jaw has a series of triangular dovetailed pockets across the top edge into which the serrated carbide inserts are placed (secured by screws). The two vertical edges of the insert that mate with walls on the pocket have a 5-degree negative angle on them that corresponds with an angle on the walls of the pocket. Thus, clamp force on the jaws translates into a downward force on the inserts and workpiece. In addition, the mating triangular shapes self-center the inserts to ensure 100 percent clearance-free contact between the workpiece and the vise jaw to absorb, not amplify, vibration. Clamp force on the inserts spreads diagonally into the jaw, not straight into it.

The carbide inserts themselves have two rows of engineered teeth that penetrate the workpiece and produce push-down effect of their own. The pyramidal teeth are cut with a sharper angle on the lower edge than on the upper edge, causing the teeth to exert a push-down force on the workpiece.

Because the teeth are carbide, they never become dull. The number and design of the teeth vary according to the machining application, whether cutting standard steel, hard material or aluminum. All inserts are manufactured to ISO P30:P35 standard and are PVD coated. Inserts for standard steel are coated with TiN and have two rows of six teeth each. Inserts for titanium and hardened steels up to 54 HRC have two rows of five teeth and are coated with TiAlCn. Inserts for aluminum have two rows of three teeth, as well as “stops” between the teeth to prevent over-penetration and are coated with CrN/NbN.

The number of inserts placed in the vice jaw can be varied, with dummy inserts available to fill the unused pockets. Penetration of the teeth is minimal and is always inversely proportional to the number of inserts used, but is typically well under 0.5 mm (0.02 inch) at 4,000 kg (8,818 lbs) clamp force. Minimal penetration depth of teeth minimizes wasted material. As a bonus, the indentations on the part create locating points for resetting the workpiece, if needed, with repeatability of 0.01 mm (0.0004 inch).

Combined with OML’s CLAK parallels, the SinterGrip jaws allow fast setup for first and second operations without removal of the inserts.

Related Content

Data Matrix Codes Offer Cutting Tool Traceability

A company’s quest to discover errors in a manufacturing process has led to printing data matrix codes on its cutting tools that provide a wealth of information for both the user and this cutting tool manufacturer.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read MoreAutomation Breakthroughs Revolutionize Precision Machining for Complex Parts

Marubeni Citizen-Cincom delivers custom solutions to address some of the biggest challenges in precision machining from handling small parts, to robot integration and unique tooling needs.

Read MoreTool Path Improves Chip Management for Swiss-Type Lathes

This simple change to a Swiss-type turning machine’s tool path can dramatically improve its ability to manage chips.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read MoreDo You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More

.jpg;maxWidth=300;quality=90)