Unique Business Coincides With Unique Customers

Using Rollomatic grinding machines, as well as other grinding machines, this company manufactures micro-cutting tools ranging in size from 0.0002 inch to 0.125 inch.

Because the metalworking industry produces a countless variety of parts and serves a plethora of customers, there’s no doubt that machine shops get their fair share of unusual part production requests. However, there aren’t many companies that can say they’ve had a request to create a cutting tool that is capable of producing a harness for a fruit fly. Though in Dave Burton’s experience, he has faced this exact request. His company, Performance Micro Tool (Janesville, Wisconsin), is ready and willing to fulfill these types of requests from customers because it can.

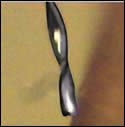

Using Rollomatic grinding machines, as well as other grinding machines, the company manufactures micro-cutting tools ranging in size from 0.0002 inch to 0.125 inch. Its tool production list includes end mills (its strength), drills, reamers and specialty tools. “Right now, we are making tools 25 times smaller than our best competitor,” says Mr. Burton, president. “We are making, by far, the smallest tools in the world.”

Performance Micro Tool produces between 60,000 to 90,000 pieces per month. About half of what it produces is custom orders, and the other half is its product line. The company sells its tiny tools to anyone who makes something small, according to Mr. Burton, which includes industries such as electronics, medical device, aerospace, communications, musical instrument and jewelry.

“About 22 to 25 percent of our sales are exports to Europe, India and Asia,” he adds. Although he has many competitors in India, he says it is his biggest export country. “They are making tools that are not quite as small as what we make, nor are the same quality as ours.”

In 2000, the company started up with three employees, and Kennametal was its biggest customer. “The group of us that started the company, we were part of one of Kennametal’s companies that shut down and moved to China,” Mr. Burton says. “There, the company discovered it could not produce small parts, so it became Performance Micro Tool’s customer.”

Currently, with ten employees, the company has moved into a new building specifically designed for the purpose of micro-cutting tool production. Visitors to the building are not greeted by the strong smell of oil, nor do they cringe from the equipment’s buzzing. The loud machines are in a soundproof room that is temperature controlled within 2°F so the machines can maintain very tight tolerances. The company’s sales volume has increased since its beginnings as well. It started out with around $400,000 in sales, reaching $2.4 million by the end of 2006.

Such a unique business as Performance Micro Tool attracts a unique customer base—hence, the fruit fly harness customer and many others. For example, the company has been involved in large projects such as NASA’s Jet Propulsion Laboratory’s Mars rover project as well as experimental projects with students from about 75 universities around the world.

“We get some pretty wacky research projects and very interesting ones, too,” he explains. “There’s a guy in Australia that is using our tools to make very small, deep cuts. He says when he hooks a solar cell up to a plate that he’s building using electron tunneling technology, the plate gets so cold that the humidity condenses on it and creates 63 liters of fresh water a day. The first thing he wants to use this technology for is to provide fresh water in areas where there’s no water.” Although the stories are interesting, Mr. Burton says he has to be skeptical. “You never know if these projects will pan out. There are so many entrepreneurs out there.”

No matter the type of customer the company attracts, it is committed to customer satisfaction. “Our motto is that if there is any kind of surprise, it has to be a good surprise,” Mr. Burton says, adding that his customers are the reason why he is in business. “Bad things can happen, and if they do, we bend over backwards to make it up to a customer.” If an order is shipped late, for example, the company will pay for shipping, or if the wrong product is shipped, the order will be free of charge.

Mr. Burton also uses his micro-tool production background to give his customers a value-added experience. He explains that when his customers’ pieces are not specified properly, he takes it upon himself to adjust the spec in order to produce the best cutting tool he can for his customers’ purposes.

Besides going out of his way to maintain customer loyalty, Mr. Burton stays abreast of new tool designs for his customers’ latest applications in order to keep a competitive edge. Currently, Performance Micro Tool has three new tool designs being sold to different marketplaces. “We do a lot of research and development,” he explains. “And when we come out with a new tool, we try to price it fairly. We can still make money, and it doesn’t put a big target on our back for all of our competitors to try to copy that tool. In fact, we sell that tool to our competitors.”

The company’s customer base will continue to grow as the micro-cutting tool production industry expands in the near future. Because the demand for even smaller parts is knocking on its door, the production of even smaller tools will become a necessity for the company. Mr. Burton says as soon as it is provided with the proper raw material for the job, Performance Micro Tool is ready to embrace this newfound work. “Right now, we are working with raw material companies to try to get a finer grain carbide raw material,” he says. “The grain sizes of this metal are 0.4 micron, so when you grind a tool as small as we do, those little chunks don’t allow for a very smooth cutting edge. There are two companies trying to work on reducing that grain size in half to 0.2 micron. Once they do that, we can try to grind even smaller tools.”

If this means producing tools to create something smaller than a harness for a fruit fly, it will be interesting to observe what new customer requests Performance Micro Tools will receive.

Related Content

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreMaking Micro Threads

Production of micro threads can be challenging, but using the most suitable tools for a given application can simplify the task.

Read MoreLaser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

Read MoreProducing Micro Screws for the Watch Industry

Cutting tools play a key role in machining tiny screws on Swiss-type lathes for this Switzerland-based watch manufacturer.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)