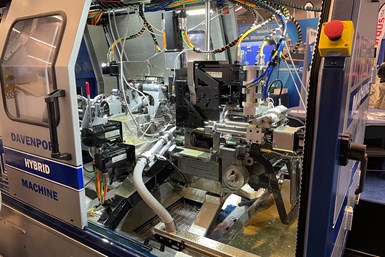

Introduced in 2017, the Hybrid multi-spindle machine combines CNC and cam-driven functionality for precision part production in high volumes.

“These are two questions we commonly receive about our Hybrid multi-spindle platform,” says Dan Bavineau, chief manufacturing and technology officer for Davenport Machine (part of Brinkman International Group Inc.).

The Hybrid concept, which represents the next evolution of the company’s heritage five-spindle, multi-spindle screw machine, combines CNC technology with some familiar cam-driven functionality which Bavineau says enables these machines to realize fast cycle times while offering tighter process control and precision. He notes it was also engineered to offer intuitive programming and increased flexibility at an affordable price point for a high-production, multi-spindle offering.

To reduce machine cost, cams are still used to control the motion of the machine’s four end-working spindles commonly used for basic drilling and tapping in which the tools simply feed in and out of the part.

A number of design improvements and additions have been made since this machine’s introduction in 2017. You can read about those at gbm.media/thehybrid. But, the company still fields questions about what elements of the machine remain cam driven and for what reasons.

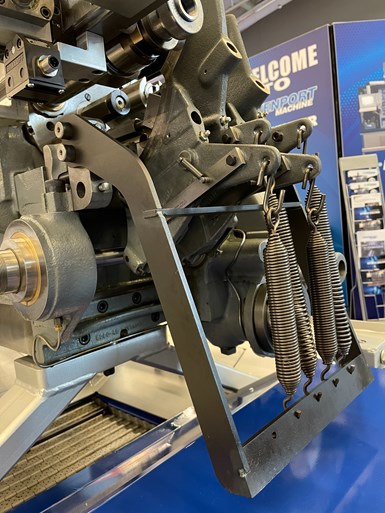

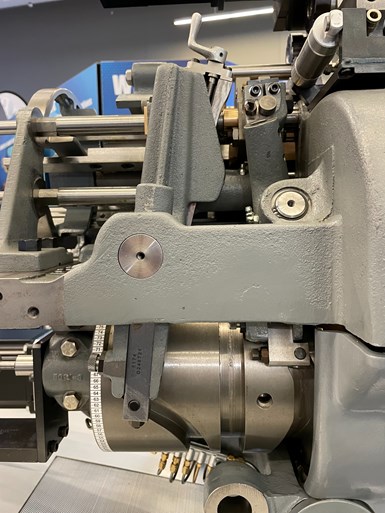

As Bavineau explains, cams are still used to control the motion of the machine’s four end-working spindles commonly used to drill, tap or slot. To give the CNC functionality would require additional components such as ballscrews, encoders, servomotors and electronics that would greatly add to the machine’s overall cost. Plus, the majority of end-working operations require simple motion — feeding in and feeding out — that can easily and repeatably be handled via cams. Still, these spindles are independently driven and can rotate at different speeds to optimize each end-working process.

A drum cam is used to maintain overall cycle synchronization.

In addition, the entire machine cycle runs off of a drum cam which is used to maintain overall cycle synchronization. For example, it is used to index the machine’s revolving head and drive the cam bank that moves the end-working spindles.

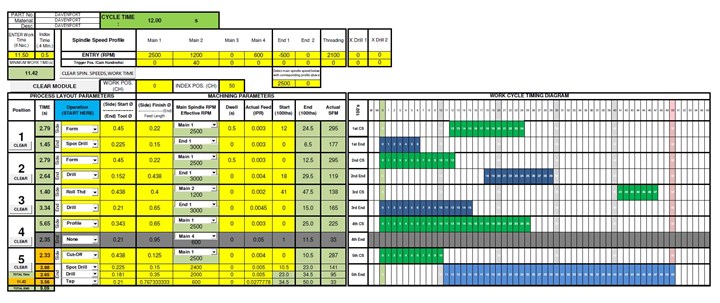

But, while there are minimal cam-driven functions in the Hybrid design, the concept of “cams” can be a concern for some, Bavineau admits. This is one reason why Davenport has developed its Layout Assist Module. This software walks users through their machining sequence by entering values such as speeds and feeds for all operations to calculate overall part cycle time. In addition, it automatically determines cam geometry and timing, enabling Davenport to design and manufacture cams for shops. Therefore, shops no longer need personnel with vast multi-spindle experience to create their own cams. Bavineau says this is a way to turn multi-spindle machining into more of a science and less of an art that would otherwise require a wealth of in-house multi-spindle tribal knowledge. Most cams ship within 24 hours after placing an order.

Davenport’s Layout Assist Module calculates overall part cycle time for users while automatically creating cam geometry. The company can then manufacture and ship the cams to users. Photo Credit: Davenport Machine

And, to further engage the industry, the company in February began offering free, weeklong training classes for both traditional heritage Davenports and the Hybrid platform at its Rochester, New York, headquarters and manufacturing campus. Those who participate pay only for transportation and lodging.

Related Content

Keeping Watch on Small Parts

From watch parts to exotic medical applications, this shop takes on the world of micromachining.

Read MoreShop Sets its Sights on Precise Tool Alignment

A Wisconsin shop has found that visual tool alignment technology has improved tool life and surface finishes for its Swiss-type lathes while increasing throughput as well.

Read More6 Tips for Training on a Swiss-Type Lathe

There are nuances to training a person to effectively operate a Swiss-type lathe. A shop I visited a while back offers some suggestions.

Read MorePursuit of Parts Collector Spearheads New Enterprise

While searching for a small parts accumulator for Swiss-type lathes, this machine shop CEO not only found what he was looking for but also discovered how to become a distributor for the unique product.

Read MoreRead Next

The Davenport Rebuild

The most difficult task for us was to overcome the reputation of the old Davenport for high prices, poor quality and bad attitude. In the last decade, we have done that, I think.

Read MoreSpeed, Process Control Combine in Refreshened Multi-Spindle Platform

A screw machine design known for its high production speed — but also its finicky nature to set up and run — has evolved to provide computer control, better accuracy and improved repeatability.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)