Chicago Innovation Days Emphasize Advanced Technology

DMG MORI Chicago Innovation Days highlighted integrated digitization, automation solutions and additive manufacturing while introducing two machines to the U.S. market.

From May 13-16, DMG MORI held its Chicago Innovation Days 2019 event in Hoffman Estates, Illinois, demonstrating the company’s latest trends and innovations in machine tool manufacturing. The event highlighted integrated digitization for planning, preparation, production, monitoring and service; automation solutions for competitive manufacturing; and additive manufacturing with four process chains in the powder bed and with the powder nozzle. The company also introduced two machines to the U.S. market.

Industrial Digitization

The trend towards industrial digitization is fundamentally altering the framework of metal cutting production technology. DMG MORI has offered digitization solutions on its machines since 2013 with the CELOS app-based control and user interface. At the same time, the company has been expanding the range of solutions it offers to create an open ecosystem for the digital factory. DMG MORI is increasing its portfolio of CELOS services with intelligent software solutions and connective hardware. Additionally, the company has established the CELOS Club, which offers customers solutions on their path to Industry 4.0 and IIoT.

Automation

Automated machines are crucial components of a digital factory and therefore an integral part of intelligent and networked production. DMG MORI views automation as a strategic future-oriented field. The production plant in Davis, California, assumes an important role in the development and implementation of automation solutions. The portfolio ranges from technical consultations and budgeting to possible machine modifications, and installation and commissioning.

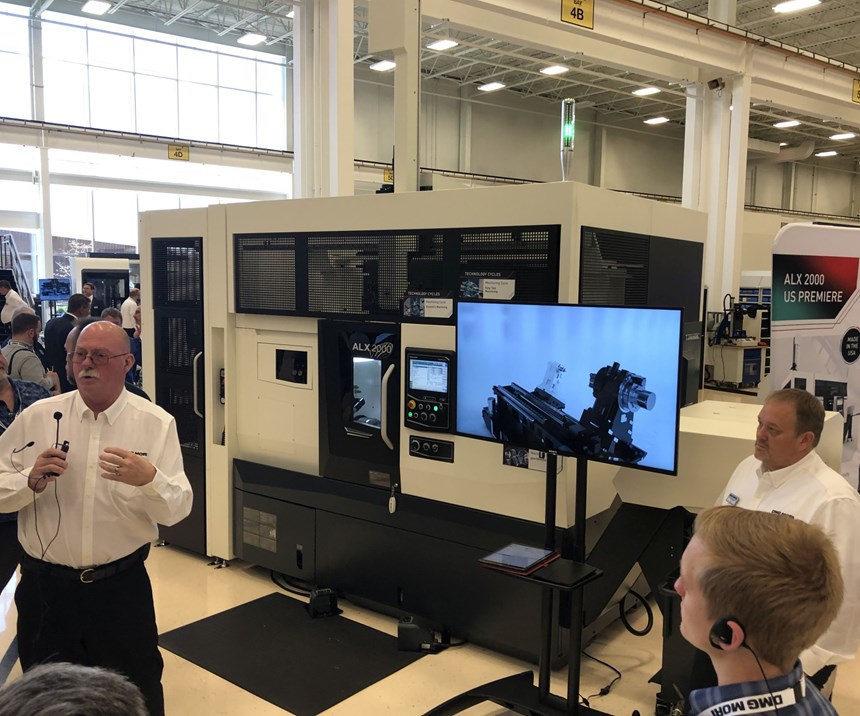

During Innovation Days, DMG MORI presented automation solutions for machines produced locally in Davis. The CMX 1100 V was equipped with modular workpiece handling and the ALX 2000—a U.S. premiere—was shown with the GX 7 gantry loader. The NHX 4000 was demonstrated with a rotary pallet storage (RPS) system for 21 pallets and the NHX 6300 with a linear pallet pool (LPP) for twelve pallets.

Additive Manufacturing

DMG MORI has been involved in the growing field of additive manufacturing for more than 20 years. The company has five Additive Manufacturing Excellence Centers (AMEC) worldwide. It also holds a 30% share in software developer InTech, which has provided key software and technological expertise for generative production. A first result of this collaboration is the new Optomet software, which InTech offers for the Lasertec SLM series machines. It has self-adjusting and learning algorithms that calculate the required parameters of the SLM process in advance within minutes.

U.S. Premieres

The ALX 2000, produced at the company’s Davis facility and shown for the first time in the U.S. at Innovation Days, is designed to be a stable, dynamic and compact turning machine that provides maximum spindle speed of 4,500 rpm and a BMT (base mount tool) turret with twelve powered tools and tailstock. The ALX 2000 also offers an optional gantry loader.

As the successor of the MillTap 700 (with more than 3,000 machines installed), the new DMP 70 is designed for maximum productivity in the smallest space. With a footprint of only a little more than 46 square feet, it is 10% smaller than the MillTap 700. It is designed for applications in medical technology and job shops, as well as the aerospace sector and other demanding industries. Travel paths of 27 x 16 x 15 inches and the optional integrated swivel/rotary table enable 5-axis simultaneous machining of a range of components. The machine was shown at Innovation Days with the workpiece handling WH 3 Cell, which can be connected from the right, left, or front of the machine.

Looking to the Future

The event featured a press conference with Dr. Mori, president of DMG MORI Co. Ltd., and Mr. James V. Nudo, President of DMG MORI USA, who discussed the company’s outlook on such topics as its goals for its U.S.-based manufacturing operations, the effects of recent tariff changes on manufacturing, efforts towards workforce development, the substantial changes occurring in the automotive market, and the company’s positioning in the additive manufacturing industry.

Related Content

High-Volume Machine Shop Automates Secondary Ops

An Ohio contract shop added a compact, self-loading CNC lathe to perform unattended secondary ops on a part for a key customer rather than running it on a manually loaded chucker.

Read MoreZoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

Read MoreAutomation in the Alps: Studer AG Unveils New Grinding Concepts

Studer AG, member company of United Grinding, held its annual press conference at its Swiss Alps location earlier this month to announce its new automatic loaders to accompany its existing grinding machines as well as other offerings and automation features.

Read MorePursuit of Parts Collector Spearheads New Enterprise

While searching for a small parts accumulator for Swiss-type lathes, this machine shop CEO not only found what he was looking for but also discovered how to become a distributor for the unique product.

Read MoreRead Next

5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read MoreEmerging Leaders Nominations Now Open

Here’s your chance to highlight a young person in your manufacturing business who is on the path to be a future leader moving your company forward.

Read More

.jpg;maxWidth=300;quality=90)