MobileCollect Wireless for Data Integrity, Accuracy

IMTS 2022: MobileCollect system is designed to give users the greatest range of options and flexibility for configuring their wireless measurement collection.

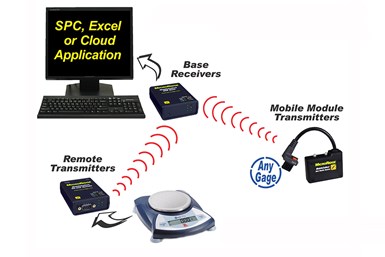

MobileCollect wireless schematic. Photo Credit: MicroRidge

MicroRidge’s MobileCollect wireless is said to enable manufacturers to achieve data integrity and accuracy in their data collection process. The company says the measurement collection system transmits measurements wirelessly from any gage into any software program — from simple spreadsheets to cloud-based SPC applications — in real-time with 100% accuracy at the press of a button.

The system is designed to be compatible with any data collection software, from Excel spreadsheets to cloud-based solutions. It also supports more than 100 gage brands and 3,5000 gage devices. Without compatibility concerns, users can select the best gage device and software solution for their needs, the company says.

A MobileCollect wireless system consists of Mobile Modules or Remotes (transmitters) and Bases (receivers). With MobileCollect, users can choose from several Mobile Module, Remote and Base options to fit users’ gaging and measurement collection requirements.

According to the company, in situations where there is heavy RF, significant machinery, robots or electrical noise, MobileCollect is often the only one that works unaffected. One Base (receiver) can connect hundreds of gages, and users can select the RF channel for communications (15 channels available). It offers 32-bit data encryption for secure transmissions. An RF Sniffer is built into the RS-232 and USB Bases (receivers) to determine available RF channels.

A setup program is not required for most configurations, but it is said the system features easy-to-use Windows setup software when needed. An Associate Mobile Module (transmitter) with Base (receiver) can be added in seconds using buttons on Mobile Modules. No operating software is needed. The system also include WedgeLink Xpress keyboard wedge software to bring users’ data into Excel and other Windows-based applications.

Related Content

-

In-Machine Probing Possibilities for VTLs

A manufacturer of vertical turning centers uses a “push/pull” optoelectronic probe with custom bracket to enable its machines to perform effective, in-process measurement of shafts and related automotive components.

-

Zoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

-

Automated Inspection Transforms Medical Manufacturer’s Quality Control

Manual steps for part inspection have been eliminated with a new CMM process using more advanced software and strategies such as using a combined scanning/touch-trigger probe.

.jpg;maxWidth=300;quality=90)