Tech Briefs

System Ensures Properly Torqued Tools

A torque-assist system that’s designed to make assembling collet tools easy and fast can help shops avoid problems associated with improperly torqued tools.

Read MoreHow to Collect and Use Machine Data

Manufacturers don’t need to limit the machine monitoring data they collect, but they do need to know how to collect the data and how to use it to drive decisions.

Read MoreSetup Options for Swiss Automatic Lathes

A hydraulic chuck and a counter-balanced centering tool, originally developed as in-house solutions, are now available to address the limited working space that is common in Swiss machining.

Read MoreRethinking the Grinding Cycle to Optimize Abrasives Cost Savings

For cost savings in grinding, the complete process should be examined, looking for a comprehensive solution using the latest technologies.

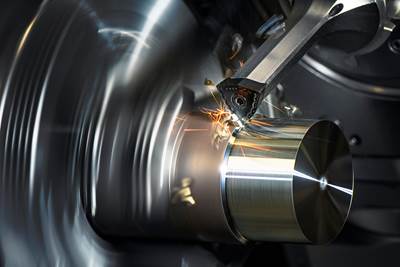

Read MoreA New Approach to CNC Turning

This turning process takes advantage of a turn-mill’s B-axis spindle to vary a tool’s approach angle to optimize chip control and feed rates.

Read MoreTiming Vacuum Impregnation with Finishing Operations

This guide determines whether vacuum impregnation should be performed before or after finishing operations.

Read MoreImproper Cobot Integration Can Cost $86,000 per Shift Operation

Cobots can improve efficiency, innovation and growth, but companies that buy them without well-defined objectives could be wasting a lot of money.

Read MoreBurr-Free Micro Thread Whirling

Threading is usually the last operation when machining components, which is why the process needs to be reliable and highly precise. DC Swiss has developed an internal thread whirler, which leaves micro threads burr-free, even in demanding, hard-to-machine materials.

Read MoreAutomated Deburring Made Simple

With its X-Bores series of deburring tools, Switzerland-based Heule has developed solutions for the automated deburring of cross bores.

Read MoreGunning for Productivity at the Spindle

Looking to improve its precision milling operations, this firearms component manufacturer went after the vibration problems that were creating poor tolerances and shortening tool life.

Read MoreHow Predictive Maintenance Can Boost a Business's Bottom Line

Predictive maintenance predicts machine failures before they occur by means of infrared thermal imaging, vibration and oil analysis, as well as integrated sensors and monitoring modules.

Read MoreWhen to Vacuum Impregnate Castings

Vacuum impregnation is an effective way to address the potential problems caused by porosity in castings, but it must be performed at the correct stage of the production process.

Read More

.JPG;maxWidth=400;quality=70)

.JPG;maxWidth=400;quality=70)

.jpg;maxWidth=300;quality=90)