Automotive

A 'HOLE' New Ballgame With Multi-Spindle Honing Systems

Automating the honing process is key to high-volume precision bore production with sub-micron accuracy.

Read MoreEnsuring Zero-Defect Bores

Here’s how one shop makes certain that every bore meets specs for customers who believe one bad part in a million is one too many.

Read MoreChip Control Solution Provides Increase In Tool Life

Replacing the traditional ISO-style inserts with a reaming system solved a chip buildup problem in bore finishing of injector bodies.

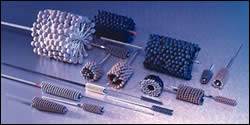

Read MoreFor Plateau Honing, Consider Ball Style

The ball-style hone is a specialized abrasive tool that is instantly recognizable by its unique appearance. For engineers in the automotive, aerospace, manufacturing and machining industries, this application-engineered hone, characterized by the small, abrasive globules that are permanently mounted to flexible filaments, is a flexible, low-cost tool for sophisticated surfacing, deburring and edge blending.

Read MoreBore Finishing Machine Increases Uptime

Tight tolerances are extremely important in gear manufacturing, and even more so when those gears are used in performance motorcycle transmissions. The ability to manufacture as competitively as possible is also a critical factor to consider.

Read MoreMonitoring Tools On A Rotary Transfer Machine

For this precision machining firm, tool monitoring is extending tool life, improving machine uptime and reducing cycle times.

Read MoreRotary Transfer Machines Help Shop Make Transition

Camcraft Precision Machined Components purchased two rotary transfer machines from Hydromat Inc. after winning a bid on an automotive plunger.

Read MoreMicrofinishing Helps Shop Meet Demanding Specs

A high-volume auto part included specifications for something Grand Haven Steel Products (Grand Haven, Michigan) had not encountered before in its bids.

Read MoreThe Dirt On Cleaner Crankshafts

A high-pressure waterjet blasts away burrs and machining residues that resist more traditional cleaning methods.

Read MoreScratching Surface Flaws With Automation

Machining parts complete on CNC multi-spindles, with automatic load and unload, is proving the key to nick- and scratch-free parts for this tier-two auto parts maker.

Read More

.jpg;maxWidth=300;quality=90)