Machine Tools

Can a Job Shop Benefit From a CNC Multi-Spindle? This One Does.

Although CNC multi-spindle machines are often dedicated to running one part or family of like parts, this Wisconsin job shop has found a way to make 20,000 parts per run its sweet spot for that equipment to better serve multiple customers.

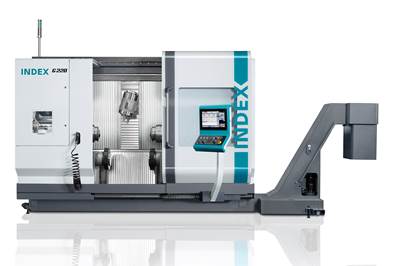

Read MoreIndex's G220 Turn-Mill for Flexible Cutting

IMTS 22: Index’s G220 turn-mill center is said to produce a wide variety of parts in a single setup.

Read MoreMarubeni Citizen-Cincom Twin-Turret Lathes for Flexible Tooling

Miyano machines are designed to ensure high rigidity, high accuracy and long life.

Read MorePrecision Machining Technology Review July 2022: IMTS Machining Centers Preview

Production Machining’s IMTS Machining Centers preview showcase includes Expand Machinery, Hardinge, Mikron Corp., DN Solutions, Kyocera Precision Tools and Mitsui Seiki.

Read MoreSwiss-Type Turning Point

This northern Ohio shop recently added its first Swiss-type lathe to gain long stretches of unattended machining largely because its continuous efforts to find new operators for its more conventional equipment had proven to be unfruitful.

Read MoreEstablishing an Effective Production Process for Femoral Balls

Grinding, honing and buffing can be performed on one machine to eliminate the need for these medical implant components to run across multiple pieces of equipment.

Read MoreMazak Syncrex Swiss-Style for Flexible, Versatile Operations

IMTS 2022: The series comes in four bar capacities, ranging from 20 to 38 mm, and is available in 7-, 8- and 9-axis configurations as well as a 9-axis model with full B-axis contouring.

Read MoreFastems Flexible Pallet Container for CNC Milling Automation

It is said the PFC 8 provides simple automation of milling machines in a smaller footprint, offering improved space efficiency and better ergonomics for operators working on either the hardware or software side.

Read MoreWhere Automated Five-Axis Machining Isn’t a Challenge

A Minnesota shop recently added a five-axis machine with integrated pallet changer to perform days-long stretches of precision, repeatable small-parts machining on its own.

WatchHow Advancements in CNC Multi-Spindles Can Put You Ahead of Current Trends

Growing economic and labor pressures are making CNC multi-spindle turn/mill technology more viable than ever. This real-world comparison to a single-spindle lathe shows how.

Watch

.jpg;maxWidth=300;quality=90)