Machine Tools

GrindSmart 660XW Hybrid Machine for Ultralean Grinding Processes

Rollomatic’s GrindSmart 660XW is a hybrid, 6‐axis tool and peel grinding machine that enables users to utilize cost‐effective and advanced lean manufacturing principles for ultralean grinding processes

Read MoreHorizontal Machining Center From Okuma Offers New Features

The machining center offers a larger work envelope, enhanced chip and coolant management functions and automation compatibility, among other features.

Read MoreNakamura-Tome SC-100X2 Optimized for Complex Part Production

Turn-mill is designed to reduce cycle times and cost per piece with superimposed machining.

Read MoreMethods’ MV-1000L Vertical Machining Center Offers Heavy-Duty Construction

The MV-1000L weighs 15,432 lbs and features a sturdy construction and premium components, enabling it to handle demanding machining challenges.

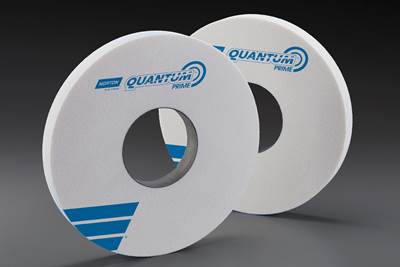

Read MoreNorton’s Quantum Prime Grinding Wheels Offer Enhanced Efficiency, Part Quality

The wheels are said to feature a microfracturing grain that has unparalleled sharpness and cutting efficiency to reduce power draw and cycle times, while increasing material removal rates.

Read MoreKurt, Absolute Machine Tools Develop Automation Package

Automation package designed to simplify integrating automation into a shop’s production processes includes a Mitsubishi LoadMate Plus, Kurt 3600A pneumatic vise and Kurt RV36 robotic gripper working in tandem with a Tongtai VP-10 mass-production, high-speed vertical machining center.

Read MoreWhat’s Still Cam-Driven and Why?

Combining select cam-driven functions with CNC technology for this multi-spindle platform is said to help reduce machine cost while retaining high machining speed, precision and production.

Read MoreFast Change Tooling System Increases Spindle Uptime

This coolant-through tooling system replacement for the gang plate on a Swiss-type machine can save hours of spindle downtime per day as well as increase tool life and enhance chip control.

WatchMaking Tribological Improvements to Bore Surfaces

A new “mechano-chemical” process that impregnates tungsten into the surface of honed bores at a nano level improves wear resistance while reducing friction between mating components.

Read MoreGenturn SL-42Y2 Swiss-type Machine for Part Size Versatility

Swiss-type machine features flexibility of a removable guide bushing to enable turning for a range of part sizes from 4 to 42 mm.

Read More

.jpg;maxWidth=300;quality=90)