Machine Tools

Moving Forward with Self-Directed Work Teams

We all deal with change in different ways. It’s critical to first, recognize, and next, do something constructive about it. The Ohio shop is well on its way on both fronts.

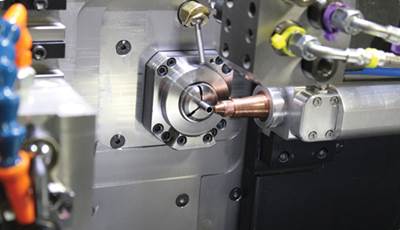

Read MoreConsolidating Operations with Swiss-Type Machines

This Ohio shop is learning about Swiss-type machines and finding how to blend the production advantages they bring into a smooth workflow. Machining parts complete in a single handling is one big advantage and a throughput goal for this shop.

Read MoreCAM System Aids with Productivity and Simplifies Complex Parts

In the case of Webber Metal Products, upgrading the CAM system was all it needed in order to increase productivity and simplify complex part production.

Read MoreAcoustic Emission Sensing Improves Productivity and Prolongs Grinding Wheel Life

In production of precision metal parts such as automotive or aerospace components, grinding to precise tolerances is of utmost importance.

Read MoreAdding Swiss to the Machining Mix

Augmenting this Ohio shop’s machining center based-business with Swiss-type machining capability speaks to trends within the metalworking industry. And it’s working well.

Read MoreTool Monitoring for Complex Machining

One of the biggest challenges to tool monitoring on a multitasking machine is coping with simultaneous cutting operations. Caron Engineering (Wells, Maine) designed a system to meet this challenge.

Read MoreLarge Threading with Single Spindle

Oilfield pipes require large, quality threads. This Texas shop is getting the performance it needs from two recently implemented big bore lathes.

Read MoreMultitasking Goes Vertical

This article looks at part processing and CNC programming considerations for vertical multitasking applications.

Read MoreThread Grinding with ‘A’ Axis

With several factors propelling a surge in demand for parts with technically complex external and internal threads with large pitches, the need for better accuracy and efficiency has created challenges.

Read More

.jpg;maxWidth=300;quality=90)