Tooling

Platinum Tooling Offers Machine-Specific Turning Center Tools

PMTS 2023: Platinum Tooling serves the automotive, aerospace, medical, firearms and energy markets, as well as many other industries in metalworking.

Read MoreWorkholding Pump Enables Creation of Specific Clamping Programs

PMTS 2023: Vektek’s Advanced Automation Workholding Pump features a step-by-step process for creating specific clamping programs.

Read MoreBlue Photon Workholding System Simplifies Part Loading

PMTS 2023: The workholding stabilizer puck simplifies how parts are loaded, reducing scrap, enabling faster feed rates and increasing spindle uptime.

Read MoreSchwanog Insertable Form Tool System for Quick Changeovers

PMTS 2023: The insertable tools are said to enable quick tool changeovers, which can result in sizable reductions in machine downtime while increasing productivity.

Read MoreFlexible, Quick-Change Tool Adapter System for Live Tools

The system significantly reduces inventory and changeover time for lathe users.

Read MorePMTS 2023 Product Preview: Cutting Tools

Learn about some of the latest cutting tool solutions that will be on display at PMTS 2023.

Read MoreDillon's Full-Grip Chuck Jaws Reduce Part Distortion

Dillon full-grip jaws are ideal for high-speed machining, as well as precision boring, tapping, drilling and finishing across most industrial markets.

WatchMicromachining Fundamentals

A number of elements must come together to establish an effective process for machining at a micro level. Here we consider four.

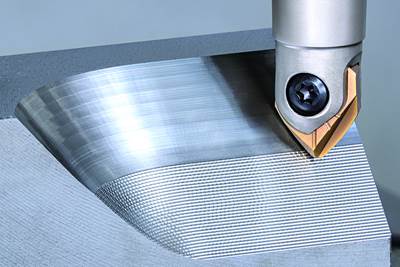

Read MoreTungaloy Barrel-Style Cutting Tool Inserts for Finishing, Semifinishing

The BallFinishNose indexable barrel-style tool inserts feature an asymmetric shape, which enables users to use the same side of the insert always facing the same direction when set in the tool body.

Read MoreBreaking the Barriers for Small Tool Breakage Detection

This contact-free tool breakage detector, especially useful for machine tools with small tools and small workzones, offers a quick and efficient way to change out broken tools before they cause bigger problems.

Read More

.png;maxWidth=300;quality=90)