It’s time to reconnect with the precision machined parts community at the Precision Machining Technology Show (PMTS) 2023 set for April 18-20, 2023, in Cleveland, Ohio, at the Huntington Convention Center. It’s the perfect opportunity to consider investing in updates for your company’s technology, automation and software to make your business more efficient and productive.

Production Machining wants to help kick off your research with a series of PMTS Product Previews. In this group, we’re taking a look at cutting tools, including a deburring tool for consistent deburring of even and uneven bore edges, a cutting concept performing multiple functions as one tool, a micro endmill for difficult-to-machine materials, and more.

Before you go to the show, don’t miss PMTS show highlights in Derek Korn’s PMTS feature article and look for more PMTS Product Previews each week until the show! And don’t forget to register for the show.

Also, you can simplify your visit to PMTS 2023 by utilizing the “My Show Planner,” which combines planning and logistics into one easy-to-use tool.

If you would like to learn more about the latest news, product technology and operational best practices in the precision machining industry, consider subscribing to Production Machining's free monthly print magazine.

Click on each link below to read the full product post:

Cofa deburring tools are designed to enable faster feed rates. Photo Credit: Heule Precision Tools

Heule Precision Tools’ Cofa tool is a universal deburring tool specifically designed for front and back deburring on even and uneven bore edges using CNC machinery. The tool is well suited for a range of cross-hole deburring applications including sloped bores. It also creates even and consistent edge breaks.

The Supermini HP can be fitted to numerous standard Supermini 105 holders as well as the ultrarigid wedge clamp system. Photo Credit: Horn

The Supermini HP system from Horn is designed for drilling, boring, facing and turning with a single high-performance tool. The cutting concept is said to enable higher infeed rates compared to standard small bore tooling. During boring, the cutting profile enables an accurate 90-degree shoulder at the base. In addition, the trailing cutting edge is engineered with a wiper geometry, designed to produce high surface qualities even at higher feed rates.

The series provides operator with tooling options that can perform well in a larger variety of setups and machines. Photo Credit: Kyocera

Kyocera has engineered a versatile line of jet coolant-through holders (JCTM) that connect directly to the turret’s internal coolant channel from the back which means they require fewer piping attachments. If the machine does not support this type of coolant, the operator can still take advantage of the holder’s coolant-through technology by connecting conventional piping to the front.

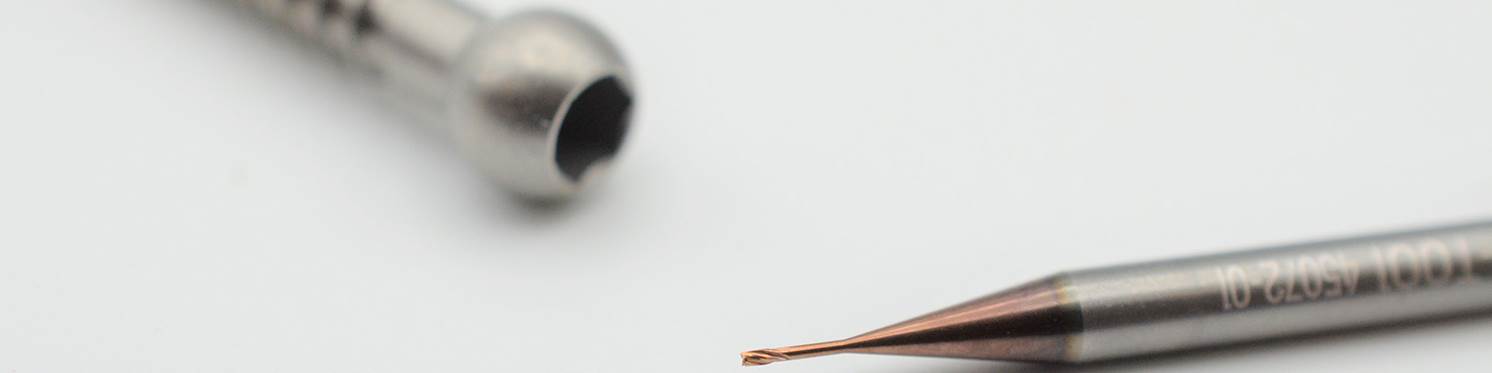

Mikron Tool’s CrazyMill Cool Micro endmill. Photo Credit: Mikron Tool

Mikron Tool’s CrazyMill Cool Micro is a micro endmill specially developed to handle difficult and very difficult-to-machine materials. It is available in diameters from .008" to .039" for a maximum milling depth of 5XD. The company says this tool represents a successful transfer of complex high-performance cutting geometries to a micro endmill.

The company will also soon be announcing its in-stock arrangement for many other lines of machine tools. Photo Credit: Platinum Tooling

Platinum Tooling is the exclusive North American importer for Heimatec live tools and angle heads, and offers live tooling for some of the most popular turning center models, including DMG Mori, Doosan, Haas, Mazak, Miyano and Nakamura. The company says it is now carrying a substantial inventory of live tools for its customers’ machines.

The insertable tools offer quick tool changeovers directly in the machine, which can result in sizable reductions in machine downtime while significantly increasing productivity. Photo Credit: Schwanog

Schwanog’s insertable form tool system is designed to offer superior quality and high efficiency in the manufacture of precision parts for industries such as medical, automotive, aerospace and others. The insertable tools can be applied to a variety of applications, including OD and ID grooving, form drilling, thread whirling, single-point threading, turning, milling, broaching of serrations, shaving, skiving and polygon turning.

The DMC drill head facilitates quick penetration into materials, enabling high precision and stable drilling without the need for a pilot hole for up to 12xD drilling depths. Photo Credit: Tungaloy

Tungaloy’s expanded DrillMeister exchangeable head drill system now includes 85 new drill heads in total of DMP, DMC and DMF drill heads in wear-resistant AH9130 grade. DrillMeister is an exchangeable head drill system said to offer both the efficiency of solid carbide drills and the productivity of indexable drills. The latest developments include the expansion of DMP drill head line.

GWS Tool Group’s Hexalobe Mill Series 2150. Photo Credit: GWS Tool Group

GWS Tool Group’s series of HexaMill micro end mills are designed for the milling of medical-grade bone screws and Torx bit sockets. Available in diameters from 0.2 mm to 1.0 mm, the 2150 HexaMill series is configured to accommodate Torx-type sizes from T4 to T30. The Hexamill end mills feature premium submicron grade carbide substrate for wear resistance and a proprietary FX7-microcoating for small-diameter end mills.

.png;maxWidth=300;quality=90)