CAD Viewer Helps with Job Estimating

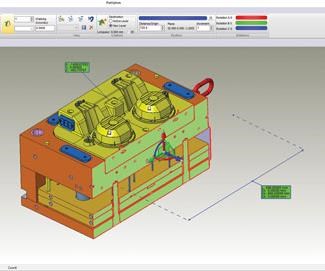

Vero Software has recently released a high speed 3D viewer that directly displays and evaluates 3D CAD files without the need for the original CAD application.

When a shop sets out to land a job, a typical early step in the process is for the potential customer to send a CAD drawing of the part to the shop for quoting. These drawings can arrive in any one of many formats. Rather than maintaining each of these CAD suites to allow viewing of whatever file format may come its way, the shop might use a CAD viewer package that will open these drawings for viewing. While a CAD viewer provides limited functionality in how it interacts with the drawing (it’s not intended for editing), it gives the user the capabilities for part analysis, dimensioning and labeling for a good overview of what the end product will require.

Vero Software has recently released a high speed 3D viewer that directly displays and evaluates 3D CAD files without the need for the original CAD application. PartXplore is designed to efficiently import and analyze all file types and sizes, often in half the time it takes to open a file in its original CAD application, the company says.

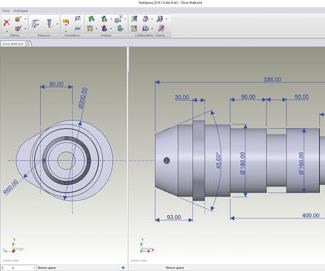

Users can build virtual unified prototypes or 3D models imported from a range of file formats, including CATIA, NX, Parasolid, SolidWorks, Solid Edge, STEP, IGES, UG and many more. The software saves the native CAD data in its own lightweight format, meaning manufacturers can carry out tasks such as calculating surface areas and volumes and measuring thickness, dimensions and angles without requiring the original CAD information.

The smaller file sizes allow users to easily send 3D parts to colleagues and subcontractors via the Internet, where the recipients can immediately display and work on the model. When sending the file, the user exports an executable file that allows the recipient to use a light version of the software for viewing. No additional software needs to be downloaded or codes activated.

The software is designed for ease of use to allow staff who are not CAD experts to still be able to take advantage of the range of 2D and 3D measurement functions using predefined selection modes such as points, 2D entities, planes and surfaces. Measurements can be automatically included as entities and anchored to characteristic points of the part. Entity labels automatically pivot to remain visible at all times.

Specialist functions allow more experienced CAD users to recover point clusters from 3D measuring equipment or machine probes and to quickly check revisions against the original CAD geometry. Point files can also be generated for sending to 3D measuring equipment and CNCs.

Annotation features allow users to add dimensional and geometric measurements, notes and labels directly to the 3D model. Ideas, observations, instructions and change requests can be easily conveyed, minimizing the need for 2D drawings.

A range of analysis tools often associated with full CAD solutions are available to assist with quoting, diagnostics of any potential difficulties, assembly notes and preparing 3D models. The inside of parts and assemblies can be explored with high-performance dynamic sectioning. With a mouse or spaceball, the section plane can be rotated and panned or can follow a guide curve. Curvature radius and plane face analysis provide accurate production times, and draft angles and undercuts can be calculated and displayed quickly, even on large components. Predefined scenes, including views of the model and different orientations, along with notes and dimensions, can be added.

Timeline animations are set up by initiating basic movements such as translation, rotation or following a guide curve. Dynamic collision analysis ensures real-time control of mechanism interoperability or process control. Short videos can also be generated. Screen captures illustrate technical documents and assembly sheets, and a large number of images can be readily managed and distributed.

This collaborative viewing software provides access to the full set of core functions to allow shop personnel to visualize, analyze and share files, but access protection ensures that only designated staff can open and work on the files.

According to Shawn Schwartz, sales and services director for the Americas at Vero, PartXplore is ideal for people working on projects coming into the shop such as quoting and estimating. “What gets people’s attention is the simple viewing and cost estimations and the low-priced value,” he says. “They don’t need a CAD system or a lot of training. Ease of use and cost effectiveness go a long way.”

Vero has set up a dedicated PartXplore website that includes a series of instructional videos demonstrating the software’s functionality and ease of use. The site also provides registration for a free 30-day trial installation.

— EDGECAM | Hexagon Manufacturing Intelligence

— WORKNC l Hexagon Manufacturing Intelligence

Related Content

Precision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

Read MoreWho Are the DFM Consultants? You Are.

Modern shops are bolstering their engineering staff to better offer design for manufacturability advice to their customers. Here, one industry expert suggests ways to develop a common language between manufacturing and engineering.

Read MoreMastercam 2024 Integrates Sandvik Coromant CoroPlus Tool Library

The integrated library enables users to work faster when importing tool geometries and cutting data.

Read MoreLone Shop Machinist Benefits From Five-Axis CAM Modules

This California shop owner applies five-axis strategies for more efficient milling of parts with challenging geometries, free-form surfaces and deep cavities.

Read MoreRead Next

Do You Have Single Points of Failure?

Plans need to be in place before a catastrophic event occurs.

Read MoreA Tooling Workshop Worth a Visit

Marubeni Citizen-Cincom’s tooling and accessory workshop offers a chance to learn more about ancillary devices that can boost machining efficiency and capability.

Read More5 Aspects of PMTS I Appreciate

The three-day edition of the 2025 Precision Machining Technology Show kicks off at the start of April. I’ll be there, and here are some reasons why.

Read More

.jpg;maxWidth=300;quality=90)