What to Consider When Adding Robotics

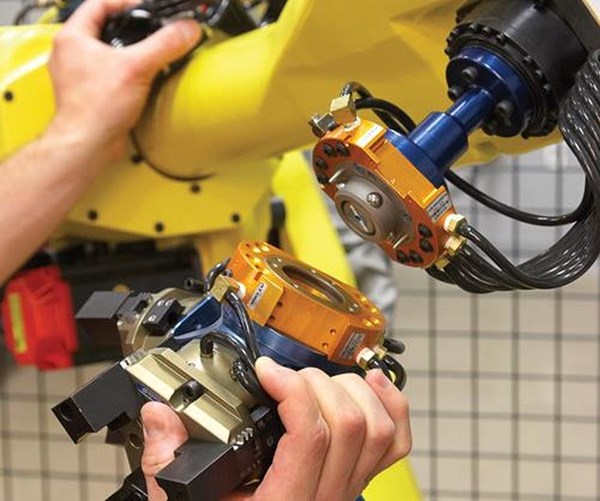

The successful implementation of robotic systems into a shop takes careful planning, from the type of robot to related components to shopfloor safety. Here’s an article that details what to consider.

Changes in technology force shops to continually adjust their production strategies in order to stay competitive. Considering how CNC control changed what happens inside the machine tool, robotic automation is having a similar impact on what happens to that process on the outside of the machine tool.

Robotics allow the combination of precision machining control with the part-exchange sequence still common today. Along with bar feeders, pallet changers and gantry loaders, robotic automation lends an additional ability of using lower cost machine tools in combination with lower cost robotic systems to help businesses be more competitive in today’s global market.

The successful implementation of robotic systems into a shop takes careful consideration. Different types of robots and their effect on operations and productivity, necessary sub-systems, and shopfloor safety all need to be taken into account. Read “Developing a Company Plan for Robotics” for a detailed strategy for re-evaluating the impact robotic automation can have on your shop’s productivity.

Related Content

-

Chuck Jaws Achieve 77% Weight Reduction Through 3D Printing

Alpha Precision Group (APG) has developed an innovative workholding design for faster spindle speeds through sinter-based additive manufacturing.

-

Zoller Event Shines Lights on Shopfloor Connectivity

The company’s open house event highlighted smart manufacturing solutions from CAM to part.

-

Tips for Troubleshooting and Repairing Chip Conveyors

A nonfunctioning chip conveyor can cause a high-production machine to be down for an extended period of time. Here is some troubleshooting advice if you’re having issues with your chip conveyors.

.jpg;maxWidth=300;quality=90)