Turning Machines

Lathes used for turning parts were the world’s first machine tools. These machines move a static cutting tool down the length of a rotating workpiece to cut the workpiece to shape. Modern CNC turning centers use servo drives to control tool motion compared to hand wheels on manual lathes. Tools install on gang plates or turrets, depending on the type of lathe. Today’s turning centers often can perform milling and cross-drilling operations thanks to live tool spindles that are installed in turret stations that sometimes provide Y-axis movement across the workpiece center line. Turning centers are available in horizontal and vertical main spindle orientations.

Latest Products

Hurco Slant-Bed Lathe Features Live Tooling Capabilities

Hurco’s TM8MYi slant-bed lathe comes equipped with a Renishaw swing-down tool setter and a bi-directional, servo-driven live tool.

Read MoreOkuma Lathe Features Rigid Construction for High-Accuracy Machining

Okuma America Corp. features the LB2000 EX III horizontal lathe, equipped with the OSP-P500 open-architecture control designed exclusively for Okuma machines.

Read MoreExpand Machinery Mill-Turn Enables Flexible Turning Performance

IMTS 2024: The Gen Turn CW 42MY is a small footprint eight-axis mill-turn lathe with a full-sized counter spindle.

Read MoreTsugami Lathe Boosts Turning Efficiency

IMTS 2024: Tsugami America showcases a multifunction sliding headstock lathe with a B-axis tool spindle.

Read MoreTrak Machine Tools Lathes Offer Compact, Heavy Duty Performance

IMTS 2024: The Trak TC2 and the Trak TC820si are compact lathes designed for production applications.

Read MoreDN Solutions Announces Twin-Spindle, Twin-Turret Horizontal Turning Center

IMTS 2024: DN Solutions introduces a twin spindle, twin-turret horizontal turning center with 4″ bar capacity for increased productivity and simultaneous machining performance.

Read MoreFeatured Posts

An Automated Answer for Machining Ball Pins

This new vertical turning center with measurement and robotic automation processes is able to produce vehicle ball joint ball pins in 7 seconds.

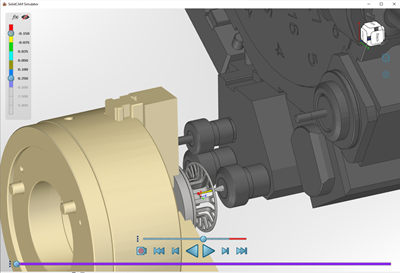

Read MoreLaser Technology "Turns" into a Turning Tool

This new technology uses a laser to act as a cutting tool to "turn" parts from solid barstock. This high-speed precision turning machine is especially useful for micromachining, enabling high accuracy for small, complex parts that are often delicate and difficult to machine when implementing conventional turning processes.

WatchPrecision Machining Technology Review: September 2024

Production Machining’s September 2024 technology showcase includes some of the latest technology from Expand Machinery, Paperless Parts, Monaghan Tooling Group, Walter USA and more.

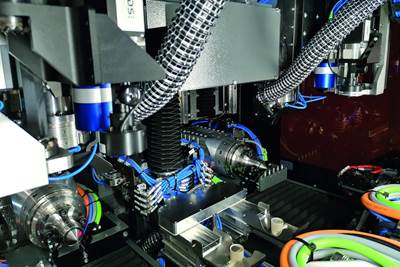

Read MoreStriving for Faster Changeovers for Multispindles

A multispindle platform designed to combine the high production speed of a cam-driven machine with the precision and repeatability of CNC also includes technology to speed set ups for new jobs.

Read MoreWhere Machining Precision is a Family Tradition

This century-old manufacturer is a case in point of how company culture and openness to adopting new technology paves the way to success.

Read MorePrecision Machining Technology Review: August 2024

Production Machining’s August 2024 technology showcase includes some of the latest technology from SW North America, Tsugami, Siemens, Select Manufacturing Technologies, Hurco and ECI Software Solutions — all on display at IMTS 2024.

Read More

.jpg;maxWidth=300;quality=90)

.jpg;maxWidth=300;quality=90)